Predictive Maintenance for CNC Routers: Monitoring Spindle Vibration and Health

|

|

Time to read 4 min

|

|

Time to read 4 min

This guide explains how to implement predictive maintenance for CNC routers, focusing on the critical task of spindle vibration monitoring. A failing spindle can cause catastrophic damage and weeks of downtime. By using industrial sensors connected to an edge gateway, you can continuously monitor the spindle's health, detect the subtle signs of impending failure, and schedule maintenance proactively. This data-driven approach is key to maximizing the uptime and lifespan of your CNC router.

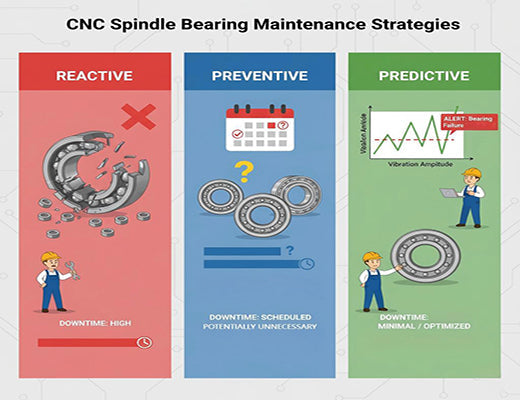

Predictive Maintenance (PdM) for a CNC router aims to fix problems before they cause a major failure, unlike reactive or preventive maintenance.

The spindle is the heart of the CNC router, and monitoring its vibration is the most effective way to predict bearing failures and other mechanical issues.

This requires a high-frequency vibration sensor connected to an edge gateway capable of performing local data analysis (edge computing).

Implementing spindle vibration monitoring can drastically reduce catastrophic failures, cut maintenance costs, and significantly boost machine availability.

Imagine the sound – that high-pitched whine or grinding noise that signals a dying spindle bearing on your main production CNC router. By the time you hear it, it's often too late. A catastrophic spindle failure doesn't just mean replacing the spindle; it often means weeks of expensive downtime waiting for parts and service, bringing your entire operation to a standstill.

What if your CNC router could tell you, weeks or even months in advance, that its spindle was starting to wear out? What if you could schedule that critical repair during planned downtime, avoiding the emergency altogether?

Let's be clear: this isn't science fiction. This is the power of predictive maintenance, and vibration analysis is its most potent tool for your CNC router.

The spindle is arguably the most critical and expensive component of your CNC router. Traditional maintenance strategies fall short:

Predictive Maintenance (PdM) offers the optimal balance:

The core principle is simple: healthy bearings have a smooth, consistent vibration "signature." As a bearing starts to wear, develop microscopic cracks, or lose lubrication, its vibration pattern changes in subtle but detectable ways.

The 'aha!' moment is realizing that a sensitive accelerometer can "hear" these changes long before a human ear can.

Implementing predictive maintenance for your CNC router, starting with spindle vibration monitoring, is one of the highest ROI investments you can make in your machine shop's reliability and profitability. It transforms maintenance from a reactive cost center into a proactive, data-driven strategy. By using the right sensors and leveraging the power of edge computing, you can truly listen to the health of your most critical assets and take action before disaster strikes.

A1: To start, you can monitor simple overall vibration levels (RMS) and look for significant increases over time. For deeper diagnostics (identifying which component is failing), more advanced analysis like FFT spectrum analysis is needed. This can be done by specialized software running on the edge gateway or by sending snapshots of data to cloud-based analysis platforms or expert consultants.

: The sensor should be mounted as rigidly as possible, directly onto the main spindle housing, ideally close to the front bearings. The mounting direction (radial or axial) depends on the type of faults you are trying to detect. Follow the recommendations of your sensor provider or a vibration analysis expert.

A3: Yes. Temperature is another key indicator, especially for detecting lubrication issues. Acoustic sensors (listening for specific sound frequencies) are also used. An all-in-one sensor like the S6000U, which includes both vibration and temperature, provides a more comprehensive picture. Spindle motor current, often available directly from the CNC router controller via the edge gateway, is another valuable data point.