Secure Remote Access for CNC Router Programming and Maintenance

|

|

Time to read 4 min

|

|

Time to read 4 min

This guide explains how to establish secure remote access for CNC router programming and maintenance. While remote monitoring provides visibility, sometimes you need hands-on access to upload G-code, adjust parameters, or perform deep diagnostics. We'll show how using a robust VPN for CNC programming, facilitated by an industrial edge gateway, creates an encrypted tunnel that allows your programmers and technicians to securely connect to the CNC router from anywhere, as if they were standing right beside it.

Secure remote access goes beyond monitoring; it allows authorized personnel to interact with and modify the CNC router's configuration remotely.

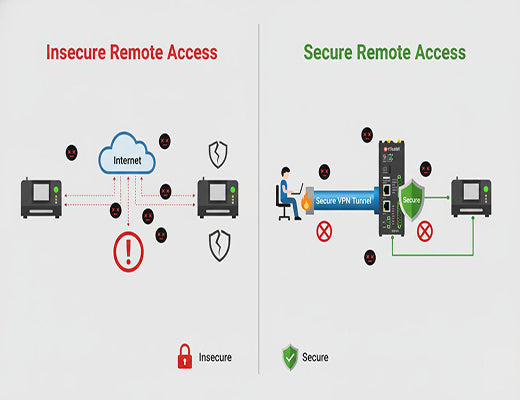

Direct exposure of a CNC router to the internet for remote access is extremely dangerous. A VPN (Virtual Private Network) is mandatory.

An industrial edge gateway acts as the secure VPN endpoint at the machine site, brokering the connection and protecting the machine tool.

Platforms like RCMS with integrated VPN solutions (like RobustVPN) can dramatically simplify the setup and management of secure remote access for an entire fleet.

Your expert CNC programmer is based at headquarters, but a critical machine needing a program update is located in a factory 500 miles away. Your options used to be limited: fly the programmer out (expensive and slow) or try to talk a local operator through a complex update (risky and error-prone). What if your expert could securely connect to that CNC router's control interface directly from their laptop, upload the new G-code, and fine-tune parameters as if they were right there?

Let's be clear: this level of secure remote access is not just possible; it's becoming a necessity for efficient, modern manufacturing. But it must be implemented with cybersecurity as the absolute top priority.

The temptation to simply forward a port on your firewall to allow direct internet access to your CNC router is immense, but the risks are catastrophic:

The architecture is straightforward:

The 'aha!' moment is realizing the edge gateway acts as a highly secure, authenticated "doorman," ensuring only authorized personnel can "talk" to the machine, and all conversations are encrypted.

Setting up and managing individual VPNs for a large fleet can be complex. A platform like RCMS simplifies this dramatically:

Providing secure remote access for CNC router programming and maintenance is a powerful enabler for modern manufacturing. It allows you to leverage your best talent anywhere in the world, respond to issues faster, and reduce operational costs significantly. By implementing this access through a robust VPN architecture, anchored by a secure industrial edge gateway, you can achieve this operational agility without compromising the critical cybersecurity of your valuable production assets.

A1: Depending on the CNC router controller's capabilities and the software you use, you can typically perform tasks like: uploading/downloading G-code programs, editing programs, modifying tool offsets and work offsets, adjusting machine parameters, viewing the live control interface, and performing advanced diagnostics.

A2: Yes, absolutely. Modern 4G LTE and 5G cellular connections offer more than enough bandwidth and low enough latency for tasks like uploading G-code files (which are typically small text files) and interacting with the controller's interface remotely.

A3: While remote desktop tools can work, they add layers of complexity and potential failure points (the PC itself). A direct VPN connection to an edge gateway is a more robust, secure, and purpose-built architecture. The gateway is an industrial device designed for 24/7 reliability, unlike a standard PC. Furthermore, managing secure access centrally via a platform like RCMS is far more scalable than managing individual remote desktop accounts.