Real-Time Tool Wear Detection for CNC Routers Using Edge AI

|

|

Time to read 5 min

|

|

Time to read 5 min

This guide explores real-time tool wear detection for CNC routers using Edge AI. Tool wear is a silent killer of quality, productivity, and profitability. By deploying specialized sensors and powerful AI models directly on an edge gateway at the machine, you can continuously monitor cutting conditions. This advanced approach moves beyond simple time-based tool changes, enabling your CNC router to dynamically adapt, ensuring optimal part quality, preventing costly tool breakage, and significantly extending tool life.

Unpredictable tool wear is a major challenge for CNC router operations, leading to poor quality, tool breakage, and wasted production time.

Real-time tool wear detection uses sensory data (like vibration, acoustic, or spindle load) combined with Edge AI to identify subtle changes indicating tool degradation.

Performing AI inference directly on an edge gateway (like the Robustel EG5120) minimizes latency, reduces cloud bandwidth, and enhances security.

This technology enables dynamic tool changes, optimizes cutting parameters, improves surface finish, and significantly reduces operational costs.

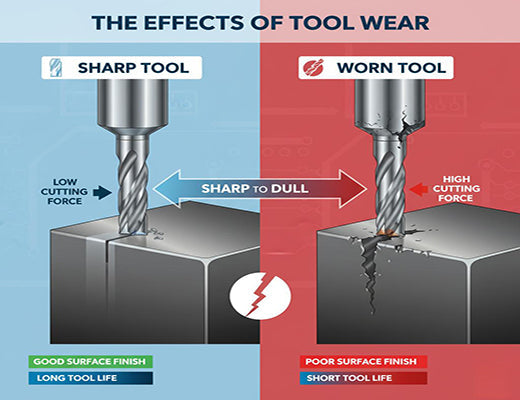

The sharpness of a cutting tool is paramount for your CNC router. A dull tool leads to poor surface finish, increased scrap, excessive force on the spindle, and eventually, catastrophic tool breakage that can damage the workpiece and even the machine itself. Yet, predicting exactly when a tool will fail or become too dull for quality work is notoriously difficult. Relying on time-based tool changes is wasteful, as many tools are replaced too early.

What if your CNC router could "feel" its tools becoming dull and tell you the exact moment they need replacing, or even adjust its cutting parameters automatically?

Let's be clear: this level of intelligent, dynamic tool management is no longer theoretical. It's becoming a reality through the combination of advanced sensing and Edge AI for CNC.

Tool wear is a complex phenomenon influenced by material, cutting parameters, and tool material. Its consequences are severe:

The 'aha!' moment is realizing that moving the AI inference to the edge at the machine significantly reduces latency, ensuring real-time response for critical cutting operations, and minimizes the amount of raw, high-frequency data that needs to be sent to the cloud.

Real-time tool wear detection for CNC routers using Edge AI represents a significant leap forward in manufacturing intelligence. It transforms tool management from a reactive, estimation-based process into a precise, data-driven optimization. By leveraging powerful edge gateways and advanced AI, you can ensure consistent part quality, dramatically reduce costs associated with tool breakage and premature replacement, and unlock unprecedented levels of efficiency and reliability for your CNC router operations.

A1: The AI model is trained using a dataset of sensor data collected from tools at different stages of wear (new, lightly worn, heavily worn, broken). This process usually involves cutting test pieces under controlled conditions, collecting data, and labeling it with the actual tool wear state. This trained model is then deployed to the edge gateway.

A2: While beneficial for many, this technology provides the highest ROI for high-precision machining, operations with expensive tools, or those involving difficult-to-machine materials where tool wear is rapid and unpredictable. Any CNC router with a Fanuc, Siemens, Haas, or similar industrial controller and the ability to interface with external sensors can be a candidate.

A3: It enhances it. While the CNC controller tracks basic tool life (e.g., number of uses or time), Edge AI for tool wear provides actual condition-based assessment. The AI can then inform the CNC's existing tool management system, making it more intelligent and precise.