Industrial IoT Edge Gateways

High-performance ARM-based industrial IoT edge gateways provide a powerful platform for local data processing, edge analytics, and control in demanding Industry 4.0 applications.

Advantages of Industrial IoT Edge Gateway Software

Powered by the open, Debian-based RobustOS Pro, these gateways offer unmatched development flexibility through Docker and a rich SDK supporting C, C++, Python, Java, Go, Node.js and more, all backed by an industry-leading 10-year Long-Term Support (LTS).

RCMS cloud platform management

Integrates fully with the RCMS cloud platform for fleet-wide monitoring, OTA updates of both the OS and applications running in containers, and secure remote access to end devices like PLCs, dramatically reducing operational costs.

IoT Edge Gateways: The Core of IoT Connectivity, Computing, and Control

With the explosive growth of Internet of Things (IoT) devices, from smart sensors to industrial PLCs, enterprises are facing an unprecedented data deluge. How to process this data efficiently, securely, and cost-effectively has become a critical challenge for digital transformation. Sending all data to the cloud is no longer the only answer. This is where Edge Computing comes in, and the IoT Edge Gateway is the core component that makes it a reality.

What Is an IoT Edge Gateway?

An IoT Edge Gateway is an intelligent hardware device that acts as the critical bridge between your local IoT devices (like sensors, cameras, actuators, PLCs) and the central cloud platform.

However, it is far more than a simple "data forwarder" or router.

Its key differentiator is "Edge Computing" capability. A true edge gateway has an powerful onboard processor, memory, and an operating system (like Linux). This allows it to perform complex tasks right at the data source—the "network edge":

-

Data Aggregation and Filtering: It can collect data from hundreds of local devices, clean and pre-process it locally, and send only valuable, summarized information to the cloud.

-

Local Analytics and Decision-Making: It can run analytics algorithms or even machine learning models directly on the device. This means it can react instantly to data (e.g., shutting down a machine upon detecting an anomaly) without waiting for instructions from the cloud.

-

Protocol Translation: The industrial (OT) world is filled with various legacy communication protocols (like Modbus, CAN bus), while the IT world uses MQTT, HTTP, etc. The edge gateway acts as an expert "translator," allowing these two worlds to communicate seamlessly.

-

Local Storage and Buffering: When the network connection is lost, it can securely store data locally and upload it once the connection is restored, ensuring zero data loss.

In short, an IoT Edge Gateway is a micro-data center deployed in the field, bringing the intelligence of the cloud closer to where the data is generated.

Why Use an IoT Edge Gateway?

If sensors can connect directly to the cloud, why add an intermediate device? The answer lies in the four core problems that edge gateways solve:

(1) Reduce Latency for Real-Time Responses

-

The Problem: In applications like smart manufacturing or autonomous vehicles, every millisecond counts. Relying on the cloud for a decision involves round-trip time (latency) that can lead to serious production failures or safety risks.

-

The Solution: An edge gateway executes decision-making logic locally. When a temperature sensor exceeds its threshold, the gateway can trigger an alarm or shut off a valve immediately, reducing response time from seconds to milliseconds.

(2) Significantly Save Bandwidth and Cloud Costs

-

The Problem: A single HD camera or a set of high-frequency vibration sensors can generate terabytes of raw data daily. Sending all this data over 4G/5G or satellite networks results in astronomical bandwidth fees and cloud storage costs.

-

The Solution: The edge gateway "refines" data locally. It can be programmed to send only "the average temperature per hour," "equipment anomaly alerts," or "video clips where a person was detected" instead of a 24/7 raw data stream, often reducing data transmission by over 90%.

(3) Enhance Data Security and Privacy

-

The Problem: In healthcare, finance, or critical infrastructure, much of the data (like patient records or factory process parameters) is highly sensitive. Regulations (like GDPR) may not permit this data to leave the local premises.

-

The Solution: The edge gateway can process and anonymize sensitive data locally. Only the non-sensitive, processed results are sent to the cloud, while the raw data remains secure behind the firewall, dramatically reducing the risk of a data breach.

(4) Improve Operational Reliability (Offline Functionality)

-

The Problem: Devices deployed in remote areas (like oil fields, wind turbines) or in moving vehicles often have unstable network connections. A total reliance on the cloud means a network outage stops all operations.

-

The Solution: An edge gateway provides powerful "offline autonomy." Even if disconnected from the cloud, it can continue to collect data, run local applications, and control field equipment. It acts as a ship's co-pilot, capable of navigating independently if contact with headquarters is lost.

Why Choose Robustel Industrial Edge Gateways?

Understanding the importance of edge gateways reveals a massive gap between consumer-grade devices and industrial-grade ones. The factory floor, the outdoor cabinet, or a vibrating vehicle presents environmental challenges far beyond a typical office.

Robustel’s Industrial IoT Edge Gateways are engineered specifically for these extreme IIoT challenges, offering reliability, flexibility, and manageability that others cannot.

(1) Ruggedized for Harsh Industrial Environments

Our industrial gateways are not "toys" meant for an air-conditioned room. They feature:

-

Wide Operating Temperature: Proven to operate stably in extreme temperatures from -40°C to +75°C.

-

Industrial-Grade Casing: Robust metal enclosures, fanless designs, and high IP/EMC ratings to withstand vibration, shock, and strong electromagnetic interference.

-

Wide Voltage Input: Support for wide-range DC power inputs (e.g., 9-60V DC) with reverse-polarity and over-voltage protection to handle unstable industrial power supplies.

(2) Ultimate Development Flexibility with RobustOS Pro

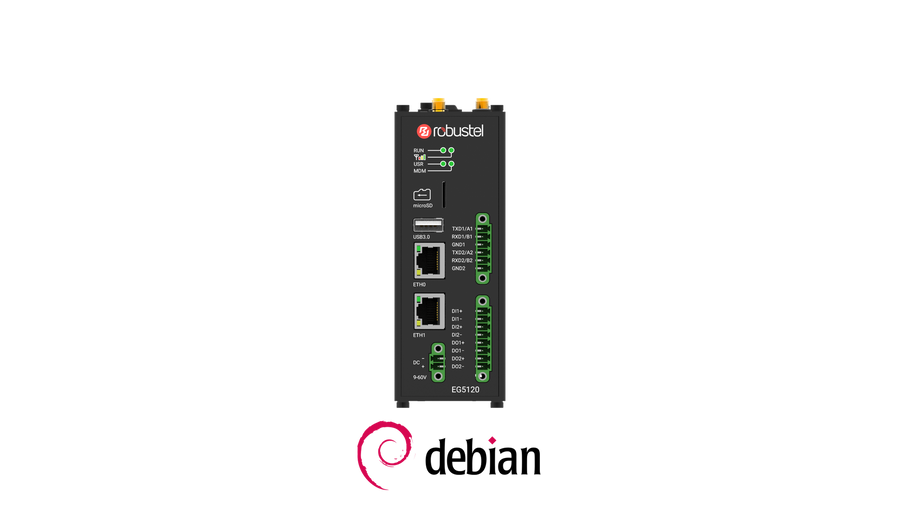

Our greatest advantage is our software. Robustel's high-end gateways (like the EG5120 series) run RobustOS Pro, an operating system based on Debian 11.

-

Docker Containerization: This means your development team is no longer locked into proprietary firmware. They can use the languages they know best (Python, C++, Java, Node.js) to package any application into a Docker container and deploy it to the gateway with one command.

-

Rapid Iteration: This open environment drastically shortens your time-to-market, allowing your edge-native applications to be developed and iterated as quickly as cloud applications.

(3) Powerful RCMS for Centralized Remote Management

Deploying thousands of gateways is just the beginning; managing them is the real challenge. Our RCMS (Robustel Cloud Manager Service) is a platform built for large-scale Operations & Maintenance (O&M):

-

Zero-Touch Provisioning: A new device can be powered on, automatically connect to the platform, and download its configuration without an engineer ever visiting the site.

-

Bulk OTA Updates: You can remotely update firmware, security patches, and even push new Docker applications to your entire fleet of gateways from a single dashboard, dramatically lowering O&M costs.

-

Secure Remote Access: Without needing expensive static IPs, RCMS allows you to create secure tunnels to remotely access and debug your gateways and their downstream devices (like PLCs) from anywhere in the world.

(4) Globally Proven Industry Expertise

Robustel has over a decade of experience in industrial cellular networking. Our Industrial IoT Edge Gateways are already empowering thousands of enterprises globally in smart manufacturing, smart cities, utilities, energy, and connected vehicles with reliable edge computing power.

Industrial IoT Edge Gateway Applications

- Smart manufacturing

- Smart building

- Smart energy

- Smart city

- Smart transportation

- Smart healthcare