Why a Cloud Platform (like RCMS) is Essential for Managing Connected CNC Routers

|

|

Time to read 4 min

|

|

Time to read 4 min

This guide explains why a dedicated cloud management platform, like Robustel's RCMS, is essential for effectively managing a fleet of connected CNC routers. While connecting your machines unlocks valuable data, managing the connectivity hardware itself (the edge gateways) across multiple sites presents significant challenges. RCMS provides the critical tools for CNC fleet management—from automated deployment and real-time monitoring to secure remote access and fleet-wide updates—transforming a potentially chaotic operation into a streamlined, secure, and cost-effective system.

Managing the connectivity gateways for your CNC router fleet is just as important as managing the CNC data itself.

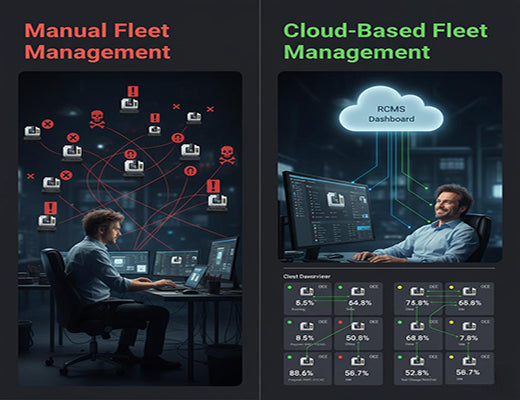

Manual gateway management is not scalable, leading to high costs, security risks, and operational inefficiencies.

A cloud platform like RCMS for CNC deployments provides essential tools for Zero-Touch Provisioning, Centralized Monitoring, Secure Remote Access (via RobustVPN), and Over-the-Air (OTA) Updates.

RCMS focuses on managing the connectivity infrastructure, complementing your SCADA/MES system which manages the machine data, creating a complete, layered management solution.

You've successfully connected your first CNC router using an industrial edge gateway. You're seeing the real-time data, calculating OEE, and maybe even preventing downtime. Now, imagine doing that for fifty machines, spread across three different factories. How do you configure all those gateways? How do you update their firmware when a security vulnerability is found? How do you even know if the gateway itself is online?

Suddenly, the connectivity that was supposed to simplify things has created a new layer of management complexity.

Let's be clear: you cannot successfully scale a connected CNC router deployment without a dedicated platform to manage the underlying connectivity infrastructure. This is the crucial role played by a cloud management platform like RCMS.

Trying to manage a fleet of edge gateways manually (e.g., via individual SSH sessions or site visits) inevitably leads to:

It's crucial to understand that RCMS is not a replacement for your SCADA, MES, or custom IoT platform for machine tools. They work together:

RCMS provides the reliable, secure, and manageable data pipeline that your application platform depends on.

Connecting a single CNC router is a technical task. Connecting and managing a fleet is an operational discipline. A cloud management platform like RCMS provides the essential tools for that discipline. It transforms the potential chaos of a large-scale deployment into a streamlined, secure, and cost-effective operation. For any business serious about leveraging data from their CNC router fleet, a robust device management platform isn't just nice to have—it's absolutely essential for success.

A1: No, RCMS focuses on managing the Robustel gateway device itself (its connectivity, status, configuration). The specific data from the CNC router (like OEE, alarms, G-code line) is collected by the gateway and then forwarded to your separate SCADA, MES, or IIoT application platform where it is processed and visualized. RCMS ensures the data gets there reliably.

A2: RCMS significantly reduces TCO primarily by minimizing operational labor costs. Zero-Touch Provisioning slashes deployment costs. Remote monitoring and troubleshooting eliminate the vast majority of expensive on-site technician visits ("truck rolls"). Fleet-wide OTA updates save countless hours of manual maintenance.

A3: Yes. Security is paramount. RCMS is hosted on secure cloud infrastructure (Microsoft Azure), uses end-to-end encryption for all communications (TLS, VPNs), undergoes regular third-party penetration testing, and offers granular role-based access control (RBAC) and detailed audit logs. Robustel's development processes are also certified to IEC 62443 standards.