Protocols and Latency in Edge Control: From Modbus to Real-Time Ethernet

|

|

Time to read 5 min

|

|

Time to read 5 min

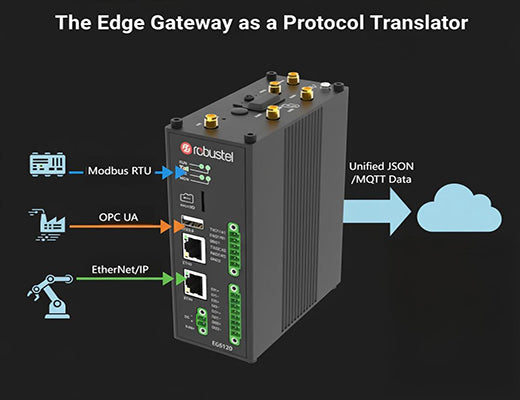

This engineer's guide explores the two most critical factors in any successful edge control system: communication protocols and network latency. We'll explain how an edge gateway must act as a multilingual "translator" for legacy protocols like Modbus and modern standards like OPC UA. More importantly, we'll break down why latency is the ultimate enemy of real-time control and how a well-architected system, built on a powerful edge gateway, minimizes this delay to achieve the deterministic performance required for high-speed industrial automation.

In edge control, communication is everything. The system's performance is dictated by its ability to "talk" to machinery (protocols) and how fast it can "think and act" (latency).

An edge gateway must be fluent in a wide range of industrial protocols, from legacy serial-based ones (Modbus RTU) to modern IP-based standards (OPC UA).

Latency, the delay between cause and effect, is the critical performance metric. Minimizing latency is the primary reason for implementing edge control over cloud control.

The edge gateway itself is a key component in the "latency budget." Its processing power and efficient software stack are crucial for minimizing the "decide" portion of the "sense-decide-act" loop.

You have a PLC that speaks Modbus RTU, a new robotic arm that communicates via Profinet, and an AI vision camera streaming over IP. Your goal: make all three work together to sort products on a conveyor belt moving at 3 meters per second. This isn't just a data collection task; this is a high-speed, real-time symphony of communication. If any one of those "conversations" is delayed by even a few milliseconds, the entire system fails.

Let's be clear: in the world of edge control, the network is the control system. Mastering the flow of information—understanding the languages of the machines and the speed of the conversation—is the fundamental engineering challenge.

An edge control system must be multilingual. The edge gateway's primary role is to act as a bridge between the diverse "dialects" spoken by your OT equipment.

A powerful edge gateway, with a flexible software platform like the Debian-based RobustOS Pro, can run the necessary drivers and applications (often in Docker containers) to speak all of these languages simultaneously.

If protocols are the language, latency is the speed of the conversation. In edge control, we're in a world where milliseconds matter.

What is Latency? Simply put, it's the delay between a cause and its effect. In our system, it's the total time from the camera seeing a defect to the rejection arm firing. This "round-trip time" is our latency budget.

The 'aha!' moment for any architect is when they break down the sources of latency:

This is precisely why cloud control fails for real-time applications. The network latency of a round-trip to a data center can be hundreds of milliseconds, completely blowing the latency budget. Edge control succeeds by reducing network latency to almost zero.

Success in edge control is a game of milliseconds. It demands a deep understanding of the protocols your machines speak and a relentless focus on minimizing every source of latency. This requires a new kind of hardware—a device that is not just a rugged computer, but a high-performance communication hub.

By choosing an industrial edge gateway like the Robustel EG5120, which combines a powerful processing core to minimize decision latency with the software flexibility to master any industrial protocol, you are equipping your system with the essential foundation for true real-time performance.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationThe Software Stack for Edge Control: OS, Containers, and RuntimesEdge Control vs. PLC: A Guide to Modern Automation Architecture

A1: A deterministic network is one that guarantees that a message will be delivered within a precise, predictable, and repeatable timeframe. This is the gold standard for high-speed, coordinated machine control, and it's the goal of technologies like TSN. While standard Ethernet is non-deterministic, a well-designed local edge control system can achieve "soft real-time" performance that is sufficient for many automation tasks.

A2: A VPN adds a small amount of processing latency due to the encryption/decryption process. On a powerful gateway like the EG5120 with hardware-accelerated encryption, this overhead is typically negligible for the control loop itself. The VPN is primarily used for the secure supervisory link to the cloud, where latency is less critical.

A3: Modbus RTU is the version of the protocol that runs over a serial line (like RS485). Modbus TCP is the version that is encapsulated in a TCP/IP packet and runs over a standard Ethernet network. An edge gateway must be able to handle both to communicate with the wide variety of devices on a factory floor.