The Core Hardware for Edge Control: From CPU/NPU to Industrial I/O

|

|

Time to read 5 min

|

|

Time to read 5 min

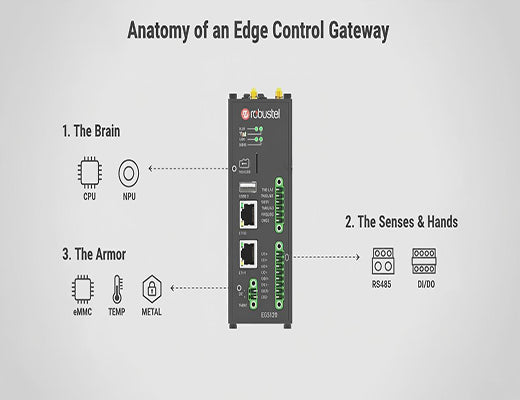

This guide provides a technical deep dive into the core hardware that enables edge control. We'll move beyond the concept to deconstruct the physical device, explaining the critical roles of three key hardware subsystems: the processing "brain" (CPU and NPU), the industrial "senses and hands" (I/O ports), and the rugged "armor" that ensures reliability. Understanding these components is essential for selecting a hardware platform that can deliver the speed, connectivity, and resilience required for real-time automation.

Edge control places unique demands on hardware, requiring a perfect balance of processing power, real-world connectivity, and industrial-grade reliability.

The processing core is a dual-engine system: a powerful CPU for running the control logic and a dedicated NPU (Neural Processing Unit) for accelerating the AI tasks that enable intelligent decisions.

Industrial I/O (like RS485 and DI/DO) is the non-negotiable bridge to the OT world, allowing the device to "talk" to and command the machinery it controls.

True industrial reliability comes from design choices like eMMC storage (vs. SD cards) and a wide temperature rating, which are hallmarks of a purpose-built edge gateway like the EG5120.

You've embraced the strategy. You're ready to move beyond simple monitoring and implement a closed-loop edge control system. Now comes the engineering challenge: what hardware can actually execute this demanding task? Can you just use any small computer?

Let's be clear: absolutely not. The hardware is not a commodity; it's a purpose-built instrument. An effective edge control system requires a specific and synergistic combination of processing power, real-world connectivity, and uncompromising reliability. It's a three-legged stool, and if any one leg is weak, the entire system will collapse.

This guide will break down that three-legged stool and show you what's under the hood of a true edge control platform.

The heart of an edge control device is its processing capability. In a modern system, this is a powerful dual-engine "brain."

The CPU is the general-purpose workhorse. Its job is to run the operating system, manage network communications, and execute the core control logic of your application (e.g., the "IF-THEN-ELSE" rules). For edge control, you need a powerful, multi-core ARM CPU that can handle multiple tasks simultaneously without getting bogged down.

This is the 'aha!' moment for anyone building an intelligent control system. An NPU is a dedicated co-processor designed for one task: running AI model inference with incredible speed and efficiency.

If the CPU/NPU is the brain, the I/O (Input/Output) ports are the nervous system that connects it to the physical world.

Without this rich set of industrial I/O, your edge "brain" is trapped in a box, unable to sense or affect the world around it.

A brilliant brain and a capable nervous system are useless if they can't survive the environment. This is where true industrial design becomes paramount.

The hardware required for edge control is a specialized instrument, not a generic computer. It requires a thoughtful balance of powerful, dual-engine processing, a rich set of real-world industrial interfaces, and a foundation of uncompromising physical reliability.

By choosing a platform like the Robustel EG5120, which has been purpose-built from the ground up with these three pillars in mind, you are not just buying a piece of hardware. You are investing in a complete, integrated, and reliable foundation for your most critical real-time automation applications.

Further Reading:

A1: TOPS stands for "Trillion Operations Per Second." It's a measure of the raw computational performance of an AI accelerator. A higher TOPS number generally means the NPU can run larger, more complex AI models or analyze data (like video frames) at a faster rate.

A2: Fans are mechanical components with a limited lifespan, and they are a common point of failure. They also pull dust and contaminants into a device. A fanless design, which uses the metal case as a passive heat sink, is inherently more reliable for long-term, maintenance-free operation in dirty industrial environments.

A3: Yes, you can use external USB or Ethernet-based I/O modules. However, this adds complexity, cost, and multiple new points of failure to your system. An integrated solution, where the I/O is part of the main device, is always more reliable and cost-effective for a professional edge control deployment.