Edge Control vs. PLC: A Guide to Modern Automation Architecture

|

|

Time to read 4 min

|

|

Time to read 4 min

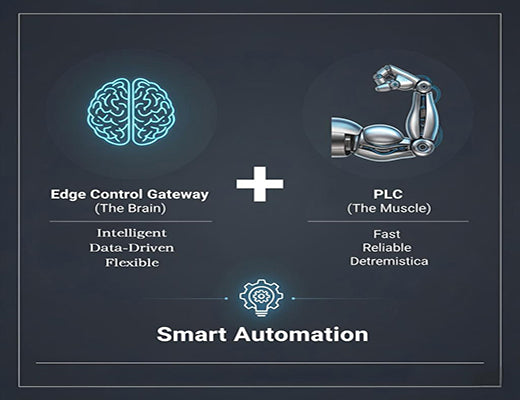

The debate of Edge Control vs. PLC is not about replacement; it's about partnership. This guide explains the distinct roles of each technology in a modern automation architecture. While the PLC remains the undisputed king of fast, deterministic, low-level machine execution, edge control—powered by an industrial gateway—acts as the intelligent "brain" or supervisor. It handles the complex, data-driven tasks that PLCs cannot, creating a powerful "brain and muscle" synergy that is the foundation of Industry 4.0.

Edge control does not replace the PLC. It enhances it by adding a layer of intelligent, data-driven decision-making.

PLC (The Muscle): Excels at high-speed, deterministic, and safe machine execution based on simple logic.

Edge Control (The Brain): Excels at analyzing complex, unstructured data (from cameras, high-frequency sensors) and running advanced algorithms or AI models.

The optimal architecture is a partnership: the edge gateway analyzes and decides, then sends a simple command to the PLC to execute. This leverages the best of both worlds.

I was on a call with a veteran automation engineer. He'd been programming PLCs for 30 years. He said, "I hear about all this 'edge' stuff. Are you telling me I need to throw out the PLCs that have been running my plant reliably for a decade and replace them with these little computers?"

It's a fear I hear often, and it's based on a fundamental misunderstanding.

Let's be clear: edge control is not a PLC killer. It is a PLC's best and smartest new partner. Trying to compare them directly is like asking what's better, a race car's engine or its driver? The question is flawed. You need both to win the race.

A Programmable Logic Controller (PLC) is a masterpiece of engineering for a specific job: hard, real-time control.

This is where the new architecture comes in. Instead of replacing the PLC, edge control adds a new, intelligent layer on top. The powerful edge gateway acts as the PLC's "brain."

The 'aha!' moment for architects is when they see the clear separation of duties:

Let's imagine an AI-powered visual sorting system on a production line.

This partnership leverages the intelligence of the edge and the deterministic reliability of the PLC.

The debate over Edge Control vs. PLC is the wrong debate. The future of industrial automation is not about replacement, but about a powerful synergy. Your existing investment in reliable PLC infrastructure is a massive asset. By adding a layer of edge control with a powerful industrial gateway, you are giving that reliable "muscle" a brilliant new "brain." This partnership is the key to building a more intelligent, more flexible, and more competitive automation architecture for the years to come.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationThe Software Stack for Edge Control: OS, Containers, and RuntimesChoosing Your Hardware: Edge Gateway vs. Industrial PC for Edge Control

A1: There are two primary methods. For modern PLCs, it can be a standard Ethernet connection, communicating via protocols like Modbus TCP or OPC UA. For a vast number of legacy PLCs, the connection is made via the gateway's industrial serial port (RS485/RS232), typically using Modbus RTU.

A2: This creates a clear and powerful separation of roles. Your OT/controls engineers continue to program and manage the safety-critical ladder logic on the PLC. Your IT/software development team can use modern languages like Python to develop the data-driven "decision" applications that run in containers on the edge gateway.

A3: Yes, dramatically. The edge gateway acts as a secure firewall, isolating your sensitive PLC network from the broader IT network. Instead of exposing multiple PLCs to the network, you only expose a single, hardened edge device, which funnels all communication through a secure, controlled point.