6 Key Business Benefits of Implementing Edge Control

|

|

Time to read 5 min

|

|

Time to read 5 min

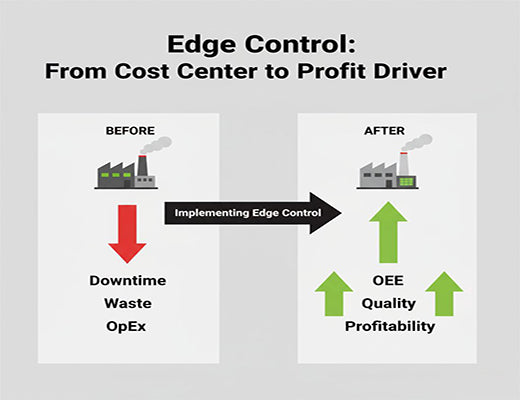

Implementing edge control is a strategic business decision that delivers a powerful and measurable return on investment (ROI). This guide moves beyond the technical details to focus on the six key business benefits this technology unlocks. From drastically reducing costly downtime and lowering operational expenses to improving product quality and enabling a new level of operational resilience, edge control is a key driver for building a more competitive, efficient, and profitable industrial operation.

Edge control directly translates into financial gains by solving the most expensive problems in manufacturing and automation: downtime and inefficiency.

The top benefits include boosting Overall Equipment Effectiveness (OEE), slashing operational costs (like cloud and bandwidth fees), and creating a more resilient operation that can function even during network outages.

It enables a higher level of quality and safety by allowing for millisecond-level responses that are impossible with human or cloud-based intervention.

Investing in an edge control platform is an investment in your company's long-term competitive advantage.

I was in a boardroom with a manufacturing executive. He said, "I have a factory full of PLCs and a subscription to a major cloud platform. We have more data than we know what to do with. Why are we still losing millions to unplanned downtime and quality issues?"

His frustration is common. Many companies have the "parts" of a smart factory but are missing the intelligent "glue" that connects them in real-time. They can monitor, but they can't instantly act.

Let's be clear: edge control is that intelligent glue. It's the technology that turns passive data into active, autonomous, and profit-driving decisions right on the factory floor. This is not just a technical upgrade; it's a business revolution.

Adopting an edge control strategy is about making a direct, positive impact on your bottom line. Here are the six most significant ways it delivers value.

Unplanned downtime is the single biggest enemy of profitability in manufacturing. Edge control fights this by enabling a truly proactive maintenance loop. An edge gateway can analyze vibration data in real-time, predict an imminent motor failure, and automatically trigger a controlled shutdown or send a command to a PLC to safely divert production, turning a catastrophic failure into a scheduled maintenance event.

Overall Equipment Effectiveness (OEE) is the gold standard for measuring manufacturing productivity. Edge control boosts all three components of OEE:

What happens to your "smart" factory when the internet connection goes down? A cloud-dependent system grinds to a halt. An edge control architecture is fundamentally resilient. Because the entire "sense-decide-act" loop is local, your production line can continue to run, make intelligent decisions, and operate autonomously even during a complete network outage.

By automating real-time decisions, edge control can make the workplace safer. An edge gateway can analyze a safety scanner's data and, if it detects a person entering a restricted robotic work cell, instantly send a "safe stop" command to the robot controller, reacting far faster than a human operator could.

An edge control system, built on an open platform like the Robustel EG5120, is programmable and adaptable. As your production needs change, you can deploy new logic in a Docker container to the edge gateway without having to perform complex and risky reprogramming of your core PLCs. This gives you an unprecedented level of operational agility.

The benefits of edge control are clear, direct, and financially compelling. This is not a technology for the sake of technology; it's a strategic tool for building a more profitable, resilient, and competitive business. By moving beyond simple monitoring and empowering your operations with real-time, autonomous decision-making at the edge, you are laying the foundation for the next generation of industrial productivity.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationEdge Control vs. Edge Monitoring: Moving from Insight to ActionIs Edge Control Right for Your Business? A 5-Point Checklist

A1: The ROI can be extremely rapid. It's calculated by comparing the project cost against the savings from reduced downtime, lower operational costs, and improved quality. In many high-value manufacturing scenarios, a successful project can pay for itself in under 12 months.

A2: No, it's a complementary technology. A PLC is a master of fast, simple, and deterministic logic. It is not designed to run an AI model, analyze a video stream, or run complex predictive algorithms. Edge control adds this layer of "data-driven intelligence" on top of the PLC's "logic-driven reliability."

A3: The best way to start is to identify your single most costly point of failure or inefficiency. Begin with a single machine or a small section of your production line. A proof-of-concept using an open platform like the EG5120 can allow you to quickly demonstrate the value and build a business case for a wider rollout.