The Architecture of Edge Computing IoT: A Blueprint for Real-Time Control

|

|

Time to read 5 min

|

|

Time to read 5 min

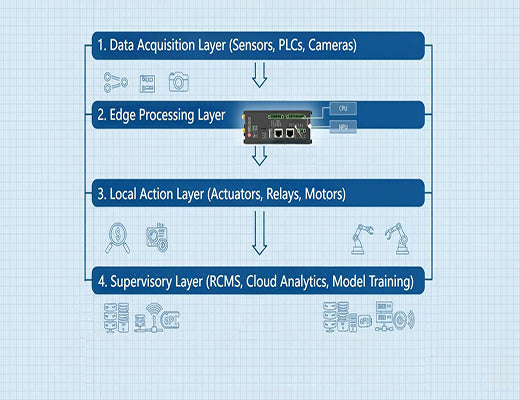

This guide provides a technical blueprint for the architecture of edge computing IoT systems designed for real-time control. We'll move beyond the "what" and focus on the "how," breaking down the four essential layers of a modern edge control loop: Data Acquisition, Edge Processing, Local Action, and Supervisory Management. This reference architecture demonstrates how a powerful edge gateway acts as the central hub, enabling the high-speed, closed-loop automation that modern industry demands.

A successful edge computing IoT architecture for control is a closed-loop system designed to "sense, decide, and act" locally in milliseconds.

The architecture consists of four distinct layers, with the Edge Gateway (like the EG5120) serving as the powerful "Edge Processing Layer" at the core.

This model uses the edge for all time-critical control tasks, while relegating the cloud to a supervisory role for management, data storage, and model training.

Key enablers for this architecture are a powerful CPU/NPU, an open OS with container support (Docker), and a rich set of industrial I/O on the edge hardware.

You understand the "why." You know that latency, cost, and reliability issues make cloud-based control impractical for high-speed industrial automation. You've embraced the concept of edge control. Now comes the next critical phase: designing the system. What does a robust, scalable, and effective edge computing IoT architecture actually look like?

Let's be clear: a successful system isn't just a collection of parts; it's a well-defined blueprint. It's a logical flow of data and commands designed for one primary purpose: real-time, closed-loop control. This guide will provide that blueprint.

This layer is the system's interface to the physical world. It's responsible for gathering the raw data needed to make an intelligent decision. This is where your edge gateway connects to:

This is the heart of the entire architecture. All the data from Layer 1 flows into a powerful industrial edge gateway like the Robustel EG5120. Its job is to execute the core logic.

Based on the decision made in Layer 2, the edge gateway takes immediate, physical action. This closes the control loop. The gateway uses its built-in industrial interfaces to:

Notice that the cloud is the final, supervisory layer, not the core of the loop. Its role is critical but not time-sensitive. The edge gateway establishes a secure connection to the cloud for:

The architecture of edge computing IoT is not just a theoretical concept; it is a practical, proven blueprint for building the next generation of industrial automation systems. By structuring your design around these four layers and placing a powerful, open, and rugged edge gateway at the center, you can build systems that are faster, smarter, more resilient, and more cost-effective than any cloud-centric model. This is how you turn the promise of real-time control into a reality on your factory floor.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationA Buyer's Guide to Edge Products: Choosing the Right Hardware for Your ApplicationBeyond Remote Access: Implementing True Edge Control for Your PLCs with the EG5120

A1: This is the key benefit of this design. Because the entire "sense-decide-act" control loop is local (Layers 1, 2, and 3), the system continues to operate with 100% functionality even if the internet connection is completely lost. It will buffer any non-critical log data and sync it with the cloud once the connection is restored.

A2: On an open platform like the EG5120 with its Debian-based OS and Docker support, you have complete freedom. You can use high-level languages like Python (with libraries like TensorFlow Lite for AI), Go, or Node.js. You can package your application and all its dependencies into a Docker container for easy, reliable deployment.

A3: The edge gateway is the perfect bridge. The gateway can run a software module that communicates with your local PLCs (via Modbus, etc.) and simultaneously acts as an OPC UA server or MQTT client, exposing all of that data in a modern, standardized format that your central SCADA system can easily consume.