Edge Control for CNC Machining: A Guide to Real-Time Optimization

|

|

Time to read 4 min

|

|

Time to read 4 min

This guide explains how edge control for CNC machining moves beyond simple monitoring to enable real-time, autonomous process optimization. By using a powerful edge gateway to analyze live sensor data, you can create closed-loop systems that detect impending tool failure and adapt machining parameters on the fly. This application of edge control transforms the CNC from a blind follower of G-code into an intelligent, self-aware craftsman, leading to dramatic reductions in tool breakage, scrapped parts, and costly downtime.

A CNC machine follows G-code perfectly, but it is "blind" to real-world conditions like a dulling tool or unexpected material hardness.

Edge control acts as a "superhuman machinist," using sensors to "listen" to the cut and making instant adjustments to prevent problems.

Key applications include real-time tool wear detection using vibration or acoustic analysis, and adaptive feed rate control based on live spindle load.

This requires a high-performance edge gateway with a dedicated NPU for AI analysis (like the EG5120) and the industrial I/O to communicate with the CNC controller.

I was talking to a CNC shop owner. He showed me a complex, high-value part worth thousands of dollars, ruined in the final seconds of a multi-hour machining job. The cause? The cutting tool, worn down after hours of work, finally broke. The machine, blindly following its G-code, didn't know. It continued its path, destroying the part and damaging the spindle.

This is the fundamental limitation of even the most advanced CNC machines. They are masters of execution, but they lack perception. They can't "feel" a dull tool or "hear" the chatter of a bad cut.

Let's be clear: you can give your machine these senses. The technology that provides this real-time perception and autonomous reaction is edge control.

A CNC's G-code program is a static script. It's a perfect plan for a perfect world. But the real world is full of variations: slight changes in material hardness, tools that wear down over time, or unexpected vibrations. The G-code cannot adapt to these changes. The machine simply executes its commands, regardless of the consequences. This is where edge control comes in, acting as an intelligent co-pilot.

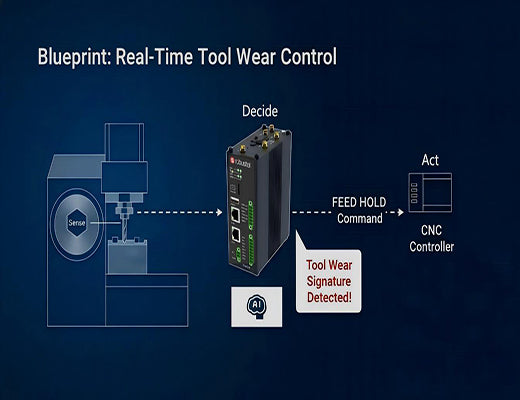

The architecture adds a new layer of intelligence that works in parallel with the CNC controller.

This is one of the highest-ROI applications for edge control in machining.

Edge control for CNC machining is about transforming your most valuable production assets from blind executors of static code into intelligent, adaptive craftsmen. It gives your machines the perception to feel problems as they develop and the autonomy to act on that information instantly. By investing in a powerful edge platform, you are not just preventing failures; you are building a more resilient, more efficient, and more profitable machine shop.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationThe Rise of the Automation Developer: New Roles in the Era of Edge ControlFrom Selling Machines to Selling Uptime: How Edge Control Enables Servitization for OEMs

A1: It depends on the CNC's age and brand. Modern controllers often have an Ethernet port and support protocols like OPC UA or Modbus TCP. Many legacy controllers use serial ports (RS232/RS485). A versatile edge gateway like the EG5120 has all of these interfaces, allowing it to connect to a wide variety of new and old machines.

A2: To create a custom model for a unique process, yes, data science expertise is needed. However, a growing number of third-party companies specialize in providing pre-trained AI models for common industrial applications like tool wear monitoring. These models can be deployed on an open edge platform like the EG5120 by an automation engineer.

A3: This is another powerful edge control application. The edge gateway monitors the CNC's live spindle load. It runs an algorithm that sends real-time "feed rate override" commands to the controller, speeding up during light cuts (e.g., cutting air) and slowing down during heavy cuts to maintain a constant tool pressure. This can significantly reduce cycle times while also extending tool life.