The Future of Edge Control: AI, Digital Twins, and Autonomous Systems

|

|

Time to read 5 min

|

|

Time to read 5 min

This guide looks beyond the present to explore the exciting future of edge control. Today's systems are just the beginning. We'll examine how the convergence of three powerful technologies—advanced edge AI, high-fidelity industrial digital twins, and truly autonomous systems—will transform the factory floor. The evolution of edge control is about moving from pre-programmed automation to machines that can perceive, reason, and adapt on their own.

The future of edge control is about enabling true autonomy, where machines can handle unforeseen situations without human intervention.

This will be driven by three key technology shifts at the edge: the move from predictive to generative AI, the creation of real-time "micro" digital twins on the device itself, and the resulting emergence of truly autonomous systems.

This evolution will require even more powerful edge hardware, with a strong focus on AI acceleration (NPU) and open, flexible software platforms.

Platforms like the Robustel EG5120 are designed to be the foundation for this future, providing the computational power and open environment needed for these next-generation applications.

We've spent the last decade connecting our machines to the internet. We've spent the last few years teaching them to make simple, pre-programmed decisions at the edge. We've successfully built the foundation of edge control. But what comes next? What does the factory of 2030 look like?

Let's be clear: the journey is far from over. We are on the cusp of a new leap, moving from simple automation to true autonomy. The future of edge control is not just about making our machines faster; it's about making them smarter in ways we're only just beginning to imagine.

Today's edge AI is primarily predictive or classificatory. It can answer questions like "Is this part defective?" or "Is this motor likely to fail?"

The future is about generative AI at the edge. Imagine an edge gateway running a specialized, compact Large Language Model (LLM). An operator could ask a machine a complex question in natural language—"Why did you reject the last five parts?"—and the edge device could analyze its own sensor data and reply, "I detected a 0.2mm scratch on the upper-left quadrant, likely caused by a misaligned feeder." This moves from simple alerts to deep, contextual reasoning.

Today, a digital twin is typically a massive, complex model that lives in the cloud. It's great for high-level simulation but is too slow for real-time control.

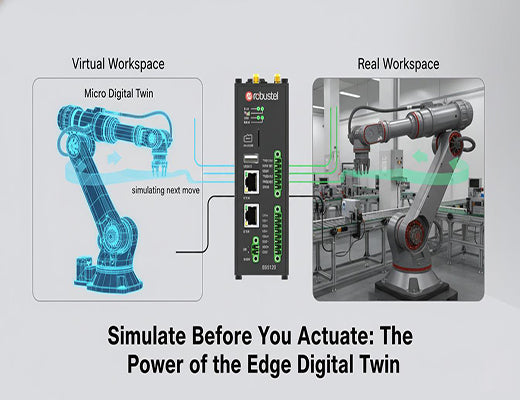

The future is about running a high-fidelity, real-time "micro digital twin" directly on the edge gateway itself.

This is the ultimate goal, where the first two trends converge.

The combination of generative AI (for reasoning) and the micro digital twin (for simulation and prediction) will enable a machine to solve problems it has never seen before. If a new, unrecognized type of product comes down the conveyor belt, an autonomous system won't just stop and throw an error. It will analyze the object, simulate the best way to pick it up, and adapt its own control logic on the fly.

The future of edge control is an exciting frontier of intelligent, adaptive, and autonomous systems. This future will not be built on the cloud; it will be built on a new generation of powerful, open, and AI-accelerated hardware at the edge. While these trends may seem futuristic, the architectural decisions we make today will determine our readiness for tomorrow. By choosing a platform like the Robustel EG5120—with its powerful NPU, open Debian-based OS, and container support—you are not just solving today's problems. You are building the foundational platform upon which the truly autonomous systems of the future will run.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationEdge Control vs. Cloud Control: Why Latency is the Deciding FactorCalculating the ROI of an Edge Control System: A Guide for Managers

A1: Not the massive models like GPT-4 that run in the cloud. However, a new and very active area of AI research is the creation of smaller, highly optimized LLMs that are specifically designed to run efficiently on edge devices with powerful NPUs, like the one in the EG5120. This is a rapidly advancing field.

A2: A cloud digital twin is a comprehensive model of an entire factory or system, used for high-level simulation and planning. An edge digital twin is a "micro" twin of a single machine or process, running locally with real-time data. Its purpose is not high-level planning, but instant, tactical decision support for the machine itself.

A3: This is the evolution towards what some are calling Industry 5.0. While Industry 4.0 was about connecting machines and collecting data (smart automation), Industry 5.0 is about creating deeper, more intelligent collaboration between humans and autonomous systems. Edge control is the core technology that enables this next leap.