Calculating the ROI of an Edge Control System: A Guide for Managers

|

|

Time to read 5 min

|

|

Time to read 5 min

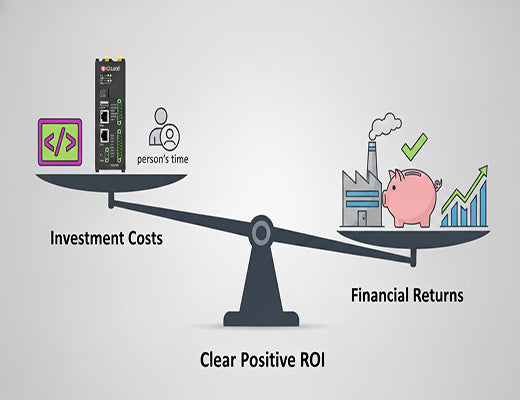

This manager's guide provides a practical framework for calculating the Return on Investment (ROI) of an edge control system. We'll move beyond the technology to focus on the numbers, breaking down how to quantify the financial gains from reduced downtime, improved OEE, and lower operational costs. By building a clear and compelling business case, you can demonstrate how an edge control project is not a cost center, but a powerful profit driver for your industrial operation.

A successful edge control project is justified by its financial return, not just its technical elegance.

he ROI calculation is a simple formula: (Financial Gains - Investment Cost) / Investment Cost.

The largest financial gains typically come from three areas: reducing unplanned downtime, boosting OEE (Overall Equipment Effectiveness), and slashing operational costs.

By quantifying these benefits, you can demonstrate a clear payback period, often in less than 12-18 months for a well-defined project.

You've identified the perfect application for edge control. You know it can make your production line faster, smarter, and more resilient. You've convinced the engineering team. Now comes the hardest part: convincing the CFO. You need to translate the technical benefits into the one language that every executive understands: Return on Investment (ROI).

Let's be clear: a successful technology project isn't just about what it does; it's about what it earns. Building a solid business case is the most critical step in getting your project funded. This guide will give you the framework to do just that.

At its core, the ROI calculation is simple. The art is in accurately quantifying the "Financial Gains." We'll break these down into the three most significant categories.

ROI = (Financial Gains - Investment Cost) / Investment Cost

Cost of Downtime per Hour x Annual Hours of Downtime Prevented

Value of Additional Units Produced - Cost of Raw Materials

Annual Cost of Manual Labor + Annual Cloud/Bandwidth Costs - New System Costs

Be transparent about the upfront and ongoing costs:

Let's build a quick business case for the widget-sorting project from our previous articles.

The ROI Calculation:

1,000,000 units x 2.5% = 25,000 widgets saved per year.25,000 widgets x $2/widget = $50,000 annual savings.($50,000 - $15,000) / $15,000 = 133% ROI.$15,000 / $50,000 = 0.3 years, or approximately 4 months.The 'aha!' moment for any CFO is seeing a clear, data-backed projection that shows a critical technology paying for itself in a matter of months.

Calculating the ROI of an edge control system transforms the conversation from a technical discussion into a strategic business dialogue. It reframes the project not as a cost to be minimized, but as a high-return investment to be prioritized. By using this simple framework to quantify the immense value of preventing downtime and boosting efficiency, you can build an undeniable business case that will get your project the green light.

Further Reading:

Is Edge Control Right for Your Business? A 5-Point Checklist6 Key Business Benefits of Implementing Edge ControlEdge Control vs. Edge Monitoring: Moving from Insight to Action

A1: The cost of downtime is highly specific to your business. A simple formula is: (Lost Revenue per Hour) + (Cost of Idle Labor per Hour) + (Fixed Costs per Hour). Lost revenue is often the largest component. For a critical production line, this can be calculated as (Units Produced per Hour) x (Profit per Unit).

A2: No, in fact, the edge control system itself often makes it easier. Because the edge gateway is collecting all the relevant production data (cycle times, good/bad part counts, uptime), it can often be programmed to calculate and report on OEE automatically, providing a clear and continuous measure of its own effectiveness.

A3: While harder to quantify, "soft" benefits are still valuable. You can estimate the financial impact of improved safety by looking at the average cost of a workplace accident (insurance, lost work time, potential fines) and multiplying it by the reduction in incident probability that your new system provides. Include these in your business case as secondary benefits.