From Selling Machines to Selling Uptime: How Edge Control Enables Servitization for OEMs

|

|

Time to read 5 min

|

|

Time to read 5 min

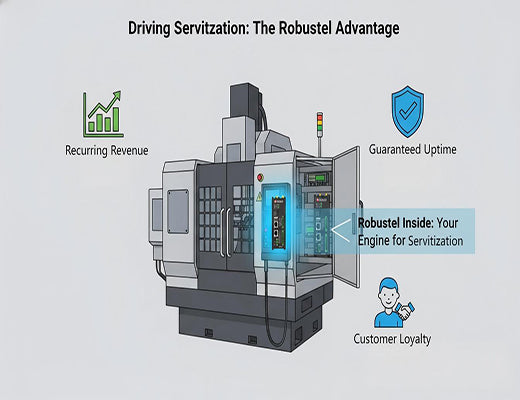

This guide explains how edge control is the core enabling technology for OEMs to transition to a servitization business model. For equipment manufacturers, this means shifting from a one-time sale of a machine to selling a long-term contract for "Uptime-as-a-Service." By embedding an intelligent edge gateway into their products, OEMs can remotely monitor, diagnose, and proactively maintain their equipment, creating a powerful recurring revenue stream and a deep, lasting customer relationship.

Servitization is the future for OEMs, offering a path to higher margins and predictable, recurring revenue.

Edge control is the technology that makes servitization possible. It provides the on-device intelligence for an OEM to monitor machine health and take proactive, autonomous action.

The architecture involves an edge gateway (the "onboard service agent") embedded in the machine and a cloud platform (the "global service headquarters") for fleet management.

This model transforms an OEM's relationship with its customers from a transactional one to a long-term, value-based partnership.

I was speaking with the CEO of a company that manufactures high-end industrial pumps. "Our margins on the hardware are getting squeezed every year," he told me. "Our real expertise is in keeping these pumps running perfectly. But we only make money when we sell a new pump or a spare part after a failure. We're in the business of selling metal, but we should be in the business of selling uptime."

His dilemma is at the heart of a massive shift in manufacturing. The most forward-thinking OEMs are no longer just selling products; they are selling outcomes. This transformation is called servitization.

Let's be clear: this business model revolution is not just a new pricing strategy. It is made possible by a powerful new technology that can be embedded inside the machine itself. That technology is edge control.

A servitization business model is a strategy where a manufacturer bundles services with their products to provide a complete solution. Instead of just selling a piece of equipment, they sell a long-term contract for the value that equipment delivers.

This model is a win-win: the customer gets a guaranteed outcome with less risk, and the OEM gets a stable, high-margin, recurring revenue stream.

So, how can you possibly guarantee uptime for a machine operating thousands of miles away? The 'aha!' moment for OEMs is realizing they need to install their own "expert technician" inside every machine they ship. That expert is an edge control system.

An edge gateway, like the Robustel EG5120, embedded within the machine's control cabinet, becomes your "onboard service agent." It has two primary jobs:

A successful "Uptime-as-a-Service" offering is built on two key technological components:

The shift to a servitization business model is the most significant strategic evolution for modern equipment manufacturers. It's a path to a more profitable, more resilient, and more customer-centric future.

Edge control is the technology that makes this path possible. By embedding intelligence directly into your products, you are not just shipping a machine anymore. You are delivering a promise—a promise of performance, reliability, and uptime that forges a powerful, long-term partnership with your customers.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationThe Rise of the Automation Developer: New Roles in the Era of Edge ControlCalculating the ROI of an Edge Control System: A Guide for Managers

A1: MaaS is a specific type of servitization where a customer does not buy the machine at all. Instead, they pay a subscription fee based on its usage or output (e.g., per hour of operation, per part produced). This is a purely operational expense (OpEx) for the customer and is only possible if the OEM can use edge control to guarantee the machine's reliability and accurately measure its output.

A2: It transforms them from a reactive "firefighting" team to a proactive "health management" team. Instead of responding to angry calls about broken machines, they use data from the edge control system to schedule maintenance, optimize performance, and act as trusted advisors to the customer, which is a much higher-value role.

A3: Start with a pilot program on a new product line or with a key customer. Embed an industrial edge gateway and begin with a simple "remote monitoring and diagnostics" service. Use the data you collect to prove the value and reliability, then gradually expand your service offering to include predictive maintenance and full uptime guarantees.