The Rise of the Automation Developer: New Roles in the Era of Edge Control

|

|

Time to read 5 min

|

|

Time to read 5 min

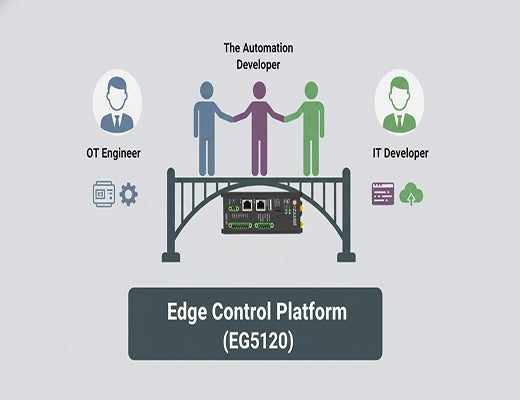

The rise of edge control is doing more than just changing technology; it's changing teams. This guide explores the emergence of a new, critical role in modern industry: the Automation Developer. This hybrid professional bridges the traditional gap between OT and IT, combining operational knowledge with modern software skills to build the next generation of intelligent automation. We'll define this role and show how an open, flexible hardware platform is the key to empowering this new breed of talent.

Edge control is breaking down the traditional silos between Operational Technology (OT) and Information Technology (IT).

This is creating a demand for a new hybrid professional, the "Automation Developer," who understands both the physical process and the software tools.

This role is a "translator," capable of using IT tools (like Python and Docker) to solve OT problems (like process optimization and control).

Empowering this role requires an open platform that serves as a "shared workbench," like an edge gateway running a Debian-based OS with both low-code and pro-code options.

I was in a project meeting, and the scene was classic. On one side of the table sat the OT team. They spoke in terms of ladder logic, cycle times, and the absolute sanctity of the PLC. On the other side sat the IT team, talking about APIs, Docker containers, and cloud scalability. They were both speaking English, but they might as well have been from different planets. The project, which required connecting a machine to the cloud for intelligent analysis, was stalled in the "translation" gap.

This friction is the single biggest human challenge in Industry 4.0. But a new technology is forcing a peace treaty by creating a new, shared language. That technology is edge control.

Let's be clear: the most profound impact of edge control may not be on our machines, but on the people who manage them. It's giving rise to a new, powerful role: the Automation Developer.

To understand the new role, we must first appreciate the old divide:

An edge control system, by its very nature, lives in both worlds. It physically connects to OT machinery but runs IT software. Successfully implementing it requires answering questions that neither side can answer alone:

Answering these questions requires a new kind of thinking. It requires a translator.

The Automation Developer is that translator. This is not necessarily one person who is a world-class expert in both fields. It can be a role, a competency, or a cross-functional team. The key is the hybrid nature.

The Automation Developer understands the context of the OT world but uses the tools of the IT world. The 'aha!' moment for many organizations is realizing they need to build, hire, or train for this skill set. This professional can look at a physical manufacturing problem and see a software-based solution.

You cannot foster this new role without providing the right tools. A proprietary, locked-down system forces everyone into a single, rigid workflow. An open platform becomes a shared workbench where both OT and IT can collaborate.

A device like the Robustel EG5120 is the ideal workbench for the automation developer role:

The transition to edge control is as much a human evolution as it is a technological one. The companies that will win in the next decade of industrial automation are those that recognize this shift and begin to cultivate the hybrid talent of the Automation Developer. This starts with breaking down organizational silos and investing in open, flexible platforms that empower your existing experts to learn new skills and your new talent to apply their skills in a new domain. The future of your factory depends on the future of your people.

Further Reading:

A1: Not necessarily in-depth. They need to understand what a PLC does and how to communicate with it (e.g., understanding Modbus registers or OPC UA tags). Their job is not to write the safety-critical ladder logic, but to safely interact with the data the PLC provides and send it high-level commands.

A2: Beyond a solid software foundation (Python is a great start), the most critical skill is curiosity about the physical world. It's the desire to understand why a particular pressure reading matters or what a specific vibration frequency signifies. It's the ability to connect the data back to the machine.

A3: Start with a cross-functional pilot project. Create a small team with members from both your OT and IT departments and give them a single, well-defined edge control problem to solve using an open platform. This forced collaboration is the fastest and most effective way to start building the shared language and skills of the Automation Developer.