Edge Control: The Practical Guide to Bridging OT and IT

|

|

Time to read 5 min

|

|

Time to read 5 min

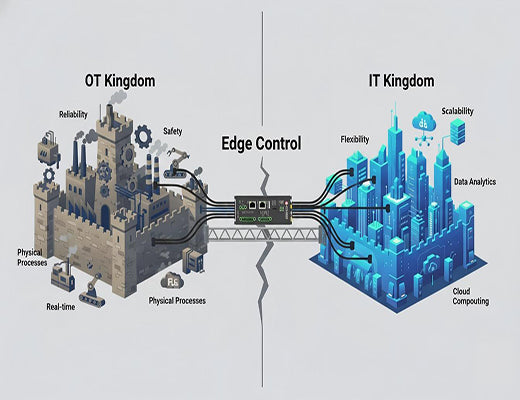

This guide defines edge control as the crucial technology enabling true OT/IT convergence right at the machine level. For decades, the deterministic world of Operational Technology (OT) and the flexible, data-driven world of Information Technology (IT) have remained in separate silos. Edge control shatters these silos by placing a powerful, IT-friendly "brain" (an edge gateway) on-site to work directly with OT equipment. This creates a resilient, high-speed, and intelligent layer that satisfies OT's need for reliability and IT's need for data, unlocking the future of industrial automation.

Edge control is the practical implementation of OT/IT convergence, moving intelligent decision-making out of the cloud and directly to the factory floor.

It resolves the core conflict between OT (which prioritizes uptime and determinism) and IT (which prioritizes data access and flexibility).

An edge gateway acts as a secure, "bilingual" bridge: it speaks OT's native protocols (like Modbus) while running modern IT software (like Docker and Python).

This architecture is the foundation for advanced applications like AI-powered process optimization and autonomous machine operation, which require both real-time control and complex data analysis.

For years, a silent war has been waged on the factory floor. It’s the conflict between two different worlds, two different philosophies: the world of Operational Technology (OT) and the world of Information Technology (IT).

The OT engineers, guardians of the production line, live by one creed: "Do not touch it. It works." Their world is about deterministic, millisecond-level control, and uptime measured in years. The IT team, on the other hand, wants to connect everything. They see the factory floor as a goldmine of data that could be used to drive efficiency and business intelligence.

This fundamental conflict has created a massive gap, preventing true digital transformation. What if there was a technology that could satisfy both sides? A technology that offers the reliability OT demands and the flexibility IT desires?

Let's be clear: that technology is edge control. It is the diplomatic bridge that ends the war between OT and IT.

At its core, edge control is a decentralized automation architecture where an intelligent edge device is placed on-site to act as a local "supervisor" and "translator" between the OT and IT worlds.

The real 'aha!' moment is realizing edge control creates a secure "demilitarized zone" where the two worlds can safely collaborate.

A successful architecture that bridges OT and IT requires a specific set of components, all embodied in a modern edge gateway like the Robustel EG5120.

Edge control is more than just a new technology; it’s a new organizational philosophy. It ends the decade-long standoff between OT and IT by providing a platform that respects the core values of both. It creates a powerful, collaborative environment right at the machine's side, unleashing a new wave of innovation in real-time process optimization, predictive control, and autonomous operation. This is the practical, achievable blueprint for the next industrial revolution.

Further Reading (The Cluster Articles):

6 Key Business Benefits of Implementing Edge ControlEdge Control vs. Edge Monitoring: Moving from Insight to ActionA Buyer's Guide to Edge Products: Choosing the Right Hardware for Your Application

A1: Yes. SCADA is a centralized supervisory system (the "S" stands for Supervisory). It's designed for humans to monitor and issue high-level commands. Edge control is a decentralized autonomous system. It's designed for the machine to control itself in real-time based on complex, local data analysis, without waiting for the central SCADA system or a human operator.

A2: Not directly. This architecture maintains a clear separation of concerns. The OT team continues to manage the core, safety-critical logic on the PLC. The IT team develops higher-level, data-driven applications that run on the edge gateway. The gateway then gives simple, high-level commands (e.g., "set speed to 1500 RPM") to the PLC, which the OT team has already programmed it to understand.

A3: When designed correctly, it dramatically improves security. The edge gateway acts as a secure, industrial-grade firewall between your sensitive OT network and the outside IT network. All communication is funneled through this single, hardened point, preventing direct, insecure access from the IT network to your critical PLCs and machinery.