Edge Control vs. Edge Monitoring: Moving from Insight to Action

|

|

Time to read 5 min

|

|

Time to read 5 min

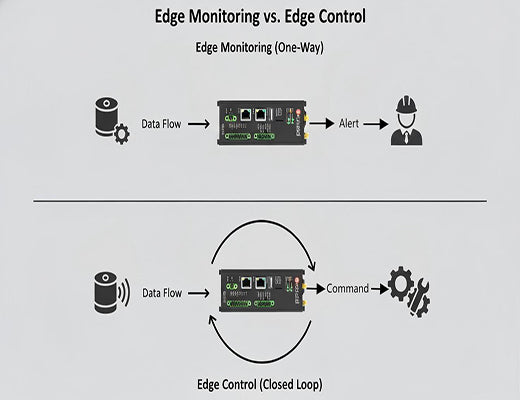

This guide clarifies the critical difference between Edge Monitoring and Edge Control. While edge monitoring is a powerful tool that provides you with valuable insights about your operations, edge control is the crucial next step that uses those insights to take immediate, autonomous action on your machinery. We'll explain how moving from this one-way data street to a closed, two-way loop is the key to unlocking true real-time automation and maximizing your operational efficiency.

Edge Monitoring is a passive, one-way process: it senses data, analyzes it, and sends you an alert. It tells you about a problem.

Edge Control is an active, closed-loop process: it senses data, analyzes it, decides on a course of action, and executes a physical command. It solves the problem.

The key difference is the "Act" step—moving from simply providing information to a human, to directly commanding a machine in real-time.

This transition from monitoring to control is what enables a higher level of automation, speed, and resilience in any industrial system.

Imagine you get a text alert from your factory's monitoring system at 2 a.m.: "Alert: Conveyor Belt #3 speed is too high for current product type." This is incredibly useful information. This is Edge Monitoring. You know there's a problem. But the problem isn't solved yet. You still have to wake up, log in remotely, and manually command the PLC to slow down the belt.

Now, imagine a different scenario. The system detects the same speed mismatch, but instead of texting you, it instantly sends a Modbus command to the belt's controller to correct the speed, all in under 50 milliseconds. The problem is solved before you even knew it existed. That is Edge Control.

Let's be clear: while they are often used interchangeably, monitoring and control are two fundamentally different concepts. Understanding this difference is the key to unlocking the next level of industrial automation.

Edge monitoring is a powerful and essential first step in any IoT journey. Its primary function is to provide visibility.

Edge Control takes that insight and makes it autonomous. It closes the loop.

The 'aha!' moment for most engineers is seeing the two concepts side-by-side.

Feature |

Edge Monitoring |

Edge Control |

System Role |

Informational (Passive) |

Operational (Active) |

Data Flow |

One-way (Data Out) |

Two-way (Data In, Command Out) |

Key Outcome |

Insight for a human/cloud |

Action by a machine |

Loop Closure |

Human or Cloud in the loop |

Machine in the loop (Closed) |

Latency Requirement |

Seconds to Minutes |

Milliseconds |

Example |

"Alert: Temperature is too high." |

"Action: Turn on cooling fan." |

Let's revisit the high-speed production line. How do these two approaches differ in the real world?

The difference between edge monitoring and edge control is profound. Monitoring gives you a perfect, real-time map of your operations. Control gives you a fleet of self-driving cars that can use that map to navigate autonomously.

While starting with monitoring is a logical and valuable first step, the true, transformative ROI in industrial automation comes from closing the loop. By choosing a hardware platform that is powerful and flexible enough to evolve from a simple monitoring device to a sophisticated control hub, you are future-proofing your investment and building a foundation for a truly intelligent and autonomous operation.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial Automation6 Key Business Benefits of Implementing Edge ControlIs Edge Control Right for Your Business? A 5-Point Checklist

A1: Yes, absolutely. A powerful edge gateway like the EG5120 can perform both functions simultaneously. It can run a control loop for a critical process while also sending summary data and alerts to a cloud platform for long-term monitoring and analysis.

A2: It can be, as it requires programming the "action" logic and integrating with the physical actuators on the machine. However, modern tools like Docker for packaging applications and low-code platforms like Node-RED for creating simple logic have dramatically lowered the barrier to entry for implementing basic control loops.

A3: No, it works in partnership with your PLC. The PLC remains the master of fast, safe, and deterministic machine logic. The edge control system acts as a smart supervisor, handling complex data analysis and giving the PLC simpler, high-level commands to execute.