How to Get Secure Remote PLC Access with an IoT Gateway & RCMS

|

|

Time to read 5 min

|

|

Time to read 5 min

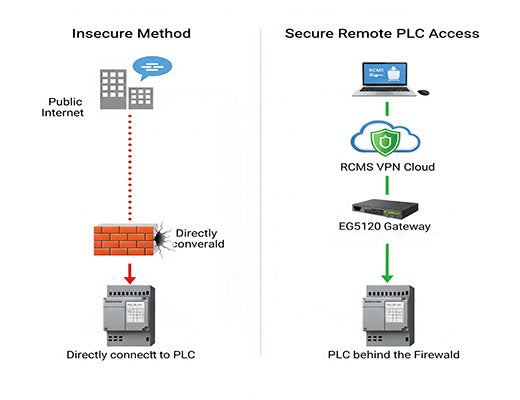

In modern industrial automation, the need to secure remote PLC access is no longer a luxury—it's a necessity for efficient troubleshooting, programming, and maintenance. But how do you do it without exposing your critical OT network to the internet?

This guide provides a step-by-step tutorial on how to achieve this using the Robustel EG5120 industrial gateway and the Robustel Cloud Manager Service (RCMS).

We'll walk through the entire process, from device setup to creating a secure VPN tunnel, enabling you to connect to your Siemens PLC from anywhere in the world as if you were right there on the factory floor.

I've spoken with countless automation engineers who share the same frustration. A machine on the factory floor stops working at 2 AM, and the PLC programmer has to drive an hour to the site, plug in a laptop, just to diagnose what might be a simple software issue. It's inefficient, costly, and incredibly stressful.

The obvious solution is remote access, but that opens a whole new can of worms. How do you provide access without punching dangerous holes in your firewall or exposing your sensitive OT network to the public internet? The answer isn't to use risky port forwarding or insecure desktop sharing software. The professional solution is to use a purpose-built Industrial IoT Edge Gateway to create a secure, encrypted tunnel directly to your PLC. This guide will show you exactly how.

The core of this solution is to never expose your PLC directly to the internet. Instead, we use the Robustel EG5120 as a secure "gatekeeper" on the local network. We then use the Robustel Cloud Manager Service (RCMS) to create an on-demand, encrypted VPN tunnel from our engineering laptop directly to the EG5120. Because the PLC is on the same local network as the gateway, we can then access it as if we were plugged in right beside it.

This architecture has three key advantages:

Unmatched Security: Your PLC remains completely invisible to the public internet. All communication is protected within an encrypted VPN tunnel.

Simplified Deployment: No complex firewall configurations or public IP addresses are needed. The gateway makes an outbound connection to the cloud, which is easy to manage.

Scalability: This same method can be used to manage hundreds of PLCs across different sites from a single, centralized platform.

Before you begin, let's get everything ready.

Hardware List:

1 x PLC device (we'll use a Siemens S7-200 Smart as our example)

An active internet connection for the EG5120 (via Ethernet or a 4G SIM card)

A Windows PC with Siemens programming software installed

Software/Accounts:

A valid Microsoft Account to register for RCMS.

An active RCMS account .

Knowledge Needed:

Basic familiarity with your PLC's IP address and network settings.

This guide will walk you through the entire process, from initial login to successfully connecting to your Siemens PLC with your engineering software.

(Note: This section's structure is preserved for easy screenshot insertion.)

In RCMS, add your EG5120 by entering its SN and MAC address , which can be found on the device's label.

Power on your EG5120 and ensure it has an internet connection.

Connect the PLC to the EG5120's Ethernet port.

t nat -A POSTROUTING -d 192.168.10.0/24 -j SNAT --to-source 192.168.10.254

In RCMS, navigate to the VPN section and create a new VPN group. Add your EG5120 to this group.

Log in to the client with your RCMS credentials and click Connect on the VPN group you created. Your PC is now securely connected to the gateway's remote network.

You've now successfully set up a system for secure remote PLC access using the EG5120 and RCMS. This method—creating a secure, on-demand VPN tunnel directly to the on-site gateway—is the professional standard for remote industrial maintenance. It eliminates the immense security risks of exposing your OT equipment to the internet while providing the flexibility and efficiency of remote operations. This is a game-changing capability for any modern industrial enterprise.

A1: Yes, it is highly secure. The PLC's IP address is never exposed to the public internet. All communication between your engineering PC and the remote site is fully encrypted within the RCMS VPN tunnel, which is based on industry-standard protocols.

A2: This is a common challenge. For PLCs with only a serial port (RS232/RS485), you can use the EG5120's serial ports and its "Transparent TCP/UDP" functionality. This creates a virtual serial port on your PC that tunnels the serial data through the secure VPN, allowing your software to connect as if it were a direct serial cable.

A3: Check the latest RCMS plans for details.