Calculating and Improving CNC Router OEE with Real-Time Data

|

|

Time to read 4 min

|

|

Time to read 4 min

This guide explains how connecting your CNC router enables automated, real-time OEE (Overall Equipment Effectiveness) calculation and provides the data needed for targeted improvements. Forget manual tracking and guesswork; we'll show you how leveraging data directly from your CNC router gives you an accurate, minute-by-minute picture of your machine's Availability, Performance, and Quality, revealing hidden inefficiencies and unlocking pathways to significantly improve CNC efficiency.

OEE is the gold standard for measuring manufacturing productivity, combining uptime, speed, and quality into a single score.

Manual OEE tracking for a CNC router is often inaccurate, time-consuming, and fails to capture the real reasons for lost productivity.

Connecting your CNC router via an edge gateway allows for automated, real-time data collection needed for accurate CNC OEE calculation.

Analyzing real-time OEE data reveals bottlenecks (like excessive setup time or minor stoppages) and empowers you to make data-driven decisions to boost your CNC router's performance.

You look at your CNC router. It seems busy, chips are flying, parts are coming off. But is it truly productive? How much time is it actually cutting versus sitting idle? Is it running at its optimal speed? Are all the parts it produces good? Without accurate data, you're flying blind, relying on gut feelings to gauge efficiency.

Many shops try to track OEE manually, using operator logs and spreadsheets. But this approach is notoriously unreliable. What if you could get a precise, automated OEE score for every CNC router, every shift, updated in real-time?

Let's be clear: you can. The key is unlocking the data stream directly from your machine. Real-time data is the foundation for accurate CNC OEE calculation and, more importantly, for driving real improvements.

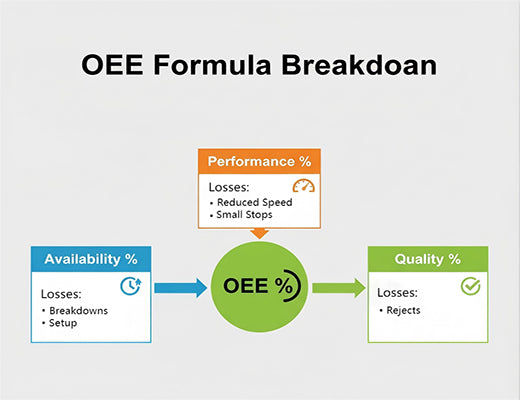

OEE (Overall Equipment Effectiveness) measures how close you are to perfect production. A score of 100% means your CNC router is producing only good parts, as fast as possible, with no stop time. It's calculated as:

OEE = Availability x Performance x Quality

Manual tracking fails because:

The 'aha!' moment is realizing that your CNC routeralready knows all this information. You just need a way to ask it. This is where an industrial edge gateway comes in. It connects directly to the CNC controller and automatically captures the necessary data points, second by second:

Simply calculating OEE isn't the end goal. The real value comes from using the data to drive improvements. A real-time CNC machine dashboard powered by this data allows you to:

Stop guessing about your CNC router's efficiency. By connecting your machine and leveraging the real-time data it generates, you can achieve automated, accurate CNC router calculation. This isn't just about getting a score; it's about gaining the visibility you need to identify problems, make targeted improvements, and unlock the full productive potential hidden within your existing equipment. Real-time data turns your CNC router from a simple tool into an active partner in your continuous improvement journey.

A1: World-class OEE is often considered to be 85% or higher. However, the average OEE in many discrete manufacturing sectors is closer to 60%. The most important thing is not the absolute number, but the trend. Consistently measuring and improving your OEE score over time is the key goal.

A2: This can be challenging. Some modern CNC router controllers have built-in part counters. In other cases, you might need to integrate data from an external source, such as a sensor on the output chute or data from a downstream quality inspection station (perhaps using AI vision connected to the same edge gateway).

A3: Yes. A powerful edge gateway like the EG5120 can run local software (e.g., in a Docker container) to collect the raw data, perform the OEE calculations in real-time, and either display the results on a local dashboard or send the calculated KPIs to your central platform. This reduces the load on your central systems.