What is an Industrial Modbus Sensor? A Guide to 7-in-1 Devices

|

|

Time to read 5 min

|

|

Time to read 5 min

If you're working in industrial automation, you know that the Industrial Modbus Sensor has been the backbone of reliable data acquisition for decades. But what does a modern one look like?

This guide provides a deep dive into the world of Modbus sensors, explaining why they are the industry standard.

We will also explore the evolution of this technology into powerful, all-in-one devices like the Robustel S6000U, a 7-in-1 industrial sensor that can dramatically simplify your IIoT projects, from predictive maintenance to environmental control.

I've spoken with countless system integrators who describe the nightmare of trying to integrate sensors that use proprietary or obscure protocols. It leads to custom drivers, complex software, and endless headaches. This is why for over 40 years, the industry has relied on a simple, robust, and open standard: Modbus.

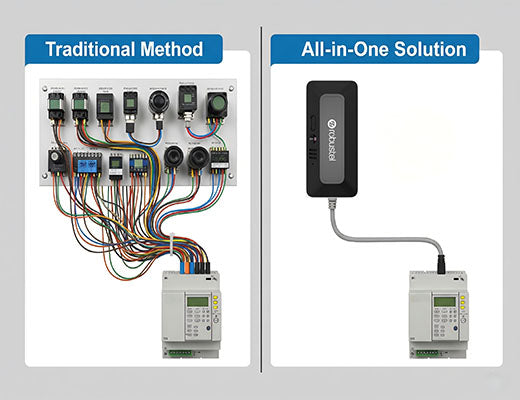

An Industrial Modbus Sensor is the solution to this chaos. It's a device that speaks the universal language of the factory floor, allowing you to connect it to virtually any piece of industrial control equipment with confidence. But not all Modbus sensors are created equal. While traditional sensors measure one thing, a new generation of all-in-one devices is changing the game. This guide will explain what to look for in a modern Industrial Modbus Sensor and how it can simplify your next project.

At its core, an Industrial Modbus Sensor is any sensor that uses the The Modbus Organization to transmit its readings. Modbus is a master-slave protocol that allows a "master" device (like a PLC or an industrial IoT edge gateway ) to poll data from one or more "slave" devices (the sensors).

Traditionally, if you needed to monitor temperature, humidity, and vibration, you would need to buy, install, and wire three separate sensors. This is where a modern, all-in-one device like the Robustel S6000U comes in. It's the next evolution of the Industrial Modbus Sensor.

The S6000U integrates seven different sensing technologies into a single, compact housing:

This approach provides a complete environmental and safety overview from one device, one cable, and one Modbus address.

The native

RS-485 Modbus RTU interface means you can connect the S6000U directly to your existing industrial equipment. The real 'aha!' moment for many engineers is realizing they can get seven data points with the same effort it used to take to get one.

Designed for real-world deployment, the S6000U is housed in a compact, lightweight,

UL94 V-0 fire-retardant enclosure. Its simple

3M adhesive installation means you can deploy it almost anywhere in seconds.

In data centers, server rooms, or chemical facilities, maintaining the right environment is critical. The S6000U can constantly monitor

temperature, pressure, and humidity, providing the real-time data needed to protect sensitive assets.

The ToF distance sensor opens up a world of possibilities in smart logistics. It can be used for collision avoidance, object detection, or for non-contact fill-level monitoring in bins and silos.

A1: Modbus RTU is a robust and widely used serial communication protocol in industrial automation. Its simplicity and reliability have made it a de facto standard for connecting industrial electronic devices for over 40 years.

A2: The S6000U is powered via its 3.5mm terminal block and accepts a wide voltage input from 9 to 24 VDC. In many installations, it can be powered directly from the PLC or gateway it's connected to.

A3: Yes, absolutely. You would need a simple USB-to-RS485 adapter to connect the sensor to the Raspberry Pi's USB port. You can then use any of the numerous open-source Modbus libraries available for Python or other languages to read the data.