Implementing Edge Control in Smart Manufacturing: A Practical Guide

|

|

Time to read 4 min

|

|

Time to read 4 min

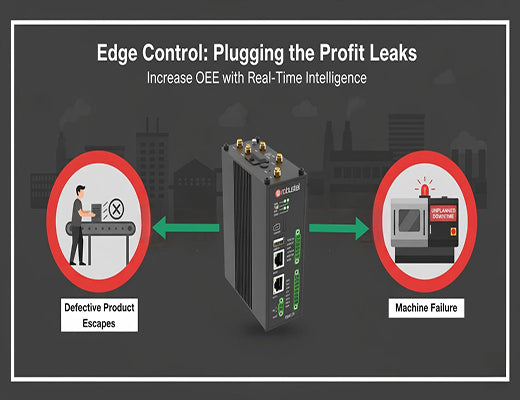

This guide provides a practical blueprint for implementing edge control in manufacturing. We'll move beyond theory to show how a powerful edge gateway can solve two of the most expensive problems on the factory floor: quality escapes and unplanned downtime. By building local, closed-loop systems for AI-powered quality inspection and predictive maintenance, edge control transforms your factory from a reactive environment to a proactive, intelligent, and more profitable operation.

Edge control in manufacturing is about creating autonomous "sense-decide-act" loops directly at the machine level.

This guide presents two high-ROI blueprints: an AI-powered quality control loop and a predictive maintenance closed loop.

The key is using an edge gateway with a dedicated NPU (for AI vision) and industrial I/O (for machine control) to make and execute decisions in milliseconds.

This approach boosts OEE by improving quality and availability, directly impacting the factory's bottom line.

I was touring a high-volume production facility. The plant manager pointed to a pallet of finished goods. "See that?" he said. "One of those has a tiny defect. If it gets to our customer, it's a hundred-thousand-dollar problem. Right now, I'm relying on a human inspector, who's about 95% accurate on a good day, to catch it." A few minutes later, we passed a critical motor that had failed unexpectedly, shutting down an entire line.

He was facing the two multi-million-dollar demons of manufacturing: imperfect quality and unplanned downtime.

Let's be clear: hoping for the best is not a strategy. You need a system that can see, think, and act faster and more reliably than a human ever could. That system is built on edge control.

A smart factory isn't just about collecting data; it's about acting on it instantly. This is where edge control delivers a massive return on investment.

This creates a tireless, 100% accurate inspector on your production line.

This creates a self-aware machine that can protect itself from catastrophic failure.

Implementing edge control in manufacturing is the tangible step that elevates your facility from a "smart" factory that collects data to a "genius" factory that acts on it autonomously. It is a practical, high-ROI strategy that directly addresses the most expensive problems in production. By leveraging a powerful and open edge platform like the EG5120, you can build these closed-loop systems to create a more resilient, more efficient, and vastly more profitable operation.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationA Buyer's Guide to Edge Products: Choosing the Right Hardware for Your ApplicationThe Architecture of Edge Computing IoT: A Blueprint for Real-Time Control

A1: While training a custom AI model requires data science skills, many third-party specialists now offer pre-trained models for common inspection tasks. The deployment of these models onto an edge gateway like the EG5120 is a straightforward process for an automation engineer, thanks to technologies like Docker.

A2: The edge gateway is the perfect bridge. While it performs the high-speed control locally, it simultaneously sends aggregated, valuable data (e.g., "5 defects detected in the last minute," "motor #3 is in safe mode") to your central SCADA/MES system for plant-wide visibility and historical analysis.

A3: Start with a single, high-impact problem. Identify the production line with the most significant quality issues or the single most critical motor that causes the most downtime when it fails. Implement one of these edge control blueprints on that single point to prove the value and ROI quickly.