Beyond Remote Access: Implementing True Edge Control for Your PLCs with the EG5120

|

|

Time to read 5 min

|

|

Time to read 5 min

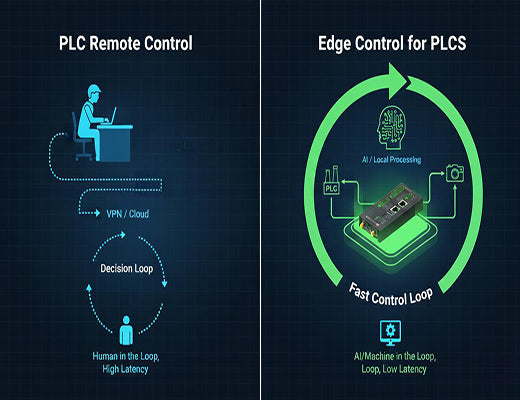

While traditional PLC remote control (via VPN) is essential for remote troubleshooting, it is a fundamentally passive process that still relies on a human in the loop. This guide explains how to go beyond simple remote access to implement true edge control for your PLCs. By using a powerful edge gateway like the Robustel EG5120 as a "local supervisor," you can run advanced, data-driven logic at the edge, analyze data from multiple sources (not just the PLC), and send intelligent commands back to the PLC in real-time.

PLC remote control is about remote access for a human. Edge Control for PLCs is about local autonomy for the machine.

The limitation of traditional remote access is that it doesn't make the system itself any smarter; it just gives an engineer a longer screwdriver.

The solution is to use an edge gateway (like the EG5120) to act as a local "brain" for the PLC. It gathers complex data (from cameras, sensors), makes an intelligent decision, and then gives a simple, actionable command to the PLC.

This architecture allows you to add advanced capabilities like AI-driven quality control or adaptive process optimization to your existing, reliable PLC systems without replacing them.

For years, the gold standard for PLC remote control has been a secure VPN connection. It's a technology we champion, and it's an indispensable tool. It allows a skilled engineer from anywhere in the world to securely log into a remote PLC, troubleshoot a problem, or update its ladder logic, saving a costly site visit.

But let's ask a critical question: does that make the machine itself any smarter? No. It just gives the engineer a much, much longer screwdriver. The system is still fundamentally reactive, waiting for a human to intervene.

What if you could install a "local expert" right next to the PLC, one that could watch, think, and act in milliseconds, 24/7? Let's be clear: you can. This is the difference between simple remote access and true edge control.

Traditional remote access is a powerful tool for maintenance, but it's not a tool for advanced automation. It's passive. It can't, for example:

To do these things, the PLC needs a smarter partner.

The real 'aha!' moment for any automation architect is when they stop thinking of an edge gateway as just a communication device, and start seeing it as a powerful, programmable co-processor for their PLC.

In this advanced architecture, the roles are clear:

Let's imagine an adaptive conveyor belt system for sorting packages.

In this model, you are leveraging the best of both worlds: the robust, real-time control of the PLC, and the data-driven intelligence of the edge gateway.

You don't need to rip out your trusted PLC systems to build the factory of the future. By moving beyond simple PLC remote control and implementing a true edge control for PLCs architecture, you can supercharge your existing automation infrastructure. A powerful and open edge gateway like the EG5120 acts as an intelligent local supervisor, adding a layer of data-driven, real-time decision-making that unlocks a new frontier of efficiency, adaptability, and intelligence for your operations.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationA Buyer's Guide to Edge Products: Choosing the Right Hardware for Your ApplicationA1: No, it complements it. The EG5120 operates at the "control" level, making millisecond decisions on the factory floor. It then sends aggregated data and event logs up to the central SCADA system, which is used for plant-wide "supervisory" monitoring and historical analysis.

A2: That's the beauty of an open platform. Because the EG5120 runs RobustOS Pro (based on Debian), your IT and development teams can use the tools they already know and love. They can write a control application in Python, package it as a Docker container, and deploy it remotely via RCMS. This is far more flexible than proprietary PLC programming environments.

A3: Yes. In this architecture, the communication between the gateway and the PLC typically happens on a private, isolated local network (either Ethernet or a serial bus). The gateway's firewall should be configured to completely isolate this sensitive OT network from the external IT network, ensuring maximum security.