Edge Control vs. MEC (Multi-access Edge Computing): A Guide for Architects

|

|

Time to read 5 min

|

|

Time to read 5 min

This architect's guide clarifies the critical distinction between Edge Control and MEC (Multi-access Edge Computing). While both fall under the "edge computing" umbrella, they occupy fundamentally different locations in the network and solve different problems. MEC brings the cloud closer to the user inside the telecom network, while edge control places intelligence directly on the machine. Understanding this "on-premise edge" vs. "network edge" distinction is crucial for designing a successful, high-performance automation architecture.

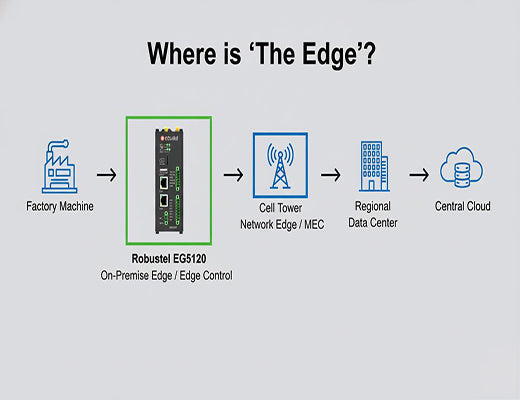

"The Edge" is not one place. The two most important locations for an industrial architect are the On-Premise Edge (your factory) and the Network Edge (the telecom provider's network).

MEC lives at the Network Edge. It's ideal for reducing latency for wide-area, mobile applications that need to be "closer" to the cloud.

Edge Control lives at the On-Premise Edge. It's essential for ultra-low latency, deterministic, and highly secure machine-level control that must operate independently.

The choice between them is not "either/or" but "which is right for the job." Mission-critical machine control requires on-premise edge control.

As an architect, you've heard the mantra a thousand times: "move compute to the edge." But a critical question is often left unanswered: where, exactly, is the edge? Is it the 5G tower at the end of the street? Or is it the ruggedized box bolted to the side of a machine inside your factory?

The answer is both. And they are not the same thing.

Let's be clear: understanding the profound architectural difference between these two "edges"—the Network Edge and the On-Premise Edge—is the key to a successful design. Confusing the two can lead to a system that is physically incapable of meeting its real-time requirements. This guide will draw a clear line in the sand.

MEC is an architecture that brings cloud computing capabilities from a distant, centralized data center and embeds them deep inside the telecommunications network, such as at a 5G base station.

Edge Control is a fundamentally different architecture. It places the compute, intelligence, and control logic on your private, on-premise network—inside your factory, your building, your facility.

The 'aha!' moment for any architect is seeing the clear trade-offs. The choice is a matter of physics and business requirements.

Architectural Criteria |

Edge Control (On-Premise) |

MEC (Network Edge) |

Location |

Inside your private facility |

Inside the Telco's network |

Latency |

<10ms (Deterministic) |

20-40ms (Variable) |

Data Privacy |

Maximum (Data stays on-premise) |

High (but data leaves your network) |

Offline Capability |

Full Autonomy |

None (Requires network connection) |

Ownership & Control |

You own and control everything |

You subscribe to a service |

Best For... |

Machine & Process Control |

Wide-Area Mobile Applications |

A powerful on-premise gateway like the Robustel EG5120 is the physical embodiment of the edge control architecture. It provides the NPU-accelerated processing, industrial I/O, and secure OS needed for this demanding environment.

The question for an architect is not whether Edge Control or MEC is "better." The right question is: "Where does my control loop need to close?"

If your application can tolerate a few dozen milliseconds of latency and requires wide-area mobility, MEC is a powerful and exciting new tool. But if your application involves high-speed machinery, mission-critical safety, or requires the absolute lowest possible latency and the highest degree of reliability, the laws of physics are clear. The loop must be closed on-premise. For these critical tasks, edge control is not just the best architecture; it is the only architecture.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationEdge Control vs. Cloud Control: Why Latency is the Deciding FactorThe Architecture of Edge Computing IoT: A Blueprint for Real-Time Control

A1: Yes, absolutely. This is a common hybrid model. A factory could use an on-premise edge control system (with EG5120s) to manage all its internal, high-speed automation. The factory could then use a 5G connection to a MEC service to coordinate its logistics with a fleet of autonomous trucks outside the factory walls.

A2: They are perfect partners for on-premise applications. A Private 5G network provides the ultra-reliable, low-latency wireless connectivity for your mobile assets within the factory (like AGVs). The edge control gateways are the brains that connect to this private network and run the applications to control those assets.

A3: Robustel's devices, like our 5G routers, act as the high-performance User Equipment (UE) that connects to a 5G network, which could be leveraging a MEC service. So while we don't provide the MEC server infrastructure itself, our hardware is the critical endpoint that allows mobile assets to take advantage of it. Our core expertise, however, is in the on-premise edge control hardware.