Edge Control in Logistics: Automating Warehouse and Fleet Operations

|

|

Time to read 4 min

|

|

Time to read 4 min

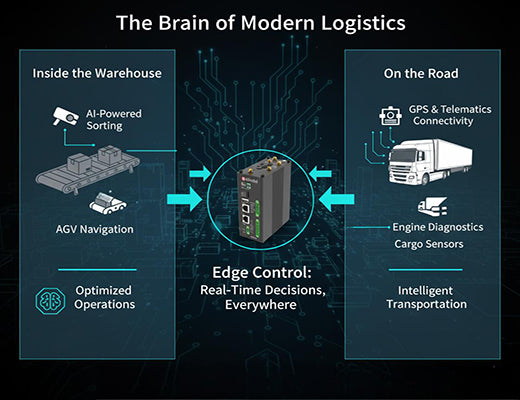

This guide explains how edge control is the key technology driving the next wave of automation in logistics, both inside the warehouse and out on the road. By deploying powerful edge gateways to make real-time, autonomous decisions, logistics companies can create highly efficient automated sorting systems, optimize the movement of robotic fleets, and transform their vehicles into intelligent mobile hubs. This decentralized approach to edge control in logistics is essential for meeting the modern demands for speed, accuracy, and operational efficiency.

In logistics, speed is everything. Edge control provides the millisecond-level latency required for high-speed warehouse automation and real-time fleet management.

In the warehouse, edge control enables AI-powered sorting and decentralized traffic management for AGV/AMR fleets, preventing collisions and maximizing throughput.

In the fleet, it allows for intelligent in-vehicle data processing, reducing cellular data costs and enabling instant, local responses to critical events (e.g., cargo temperature alarms).

This requires two types of specialized hardware: a high-performance edge gateway (like the EG5120) for stationary operations, and a rugged, vehicle-grade router (like the R5030) for mobile assets.

I was speaking with a director of a large distribution center. "We're in an arms race," he said. "Our customers expect 'next-day' or even 'same-day' delivery. Every second we waste, every package we misroute, costs us money and reputation. The manual processes that worked five years ago are now our biggest bottleneck."

His problem is universal in the logistics industry. The demand for speed and accuracy has outpaced human capability. The only way to compete is through intelligent automation.

Let's be clear: the brain of that intelligent automation is edge control. It's the technology that allows your warehouse and your fleet to think and act for themselves, at machine speed.

A modern warehouse is a symphony of high-speed motion. Edge control acts as the local conductor, ensuring every instrument plays in perfect, real-time harmony.

An edge control strategy also transforms your vehicles from simple transports into intelligent, mobile data hubs.

From the controlled chaos of the warehouse floor to the unpredictable environment of the open road, edge control is the key to building a faster, smarter, and more resilient logistics operation. It provides the low-latency, autonomous decision-making required to automate tasks that were previously impossible. By deploying the right specialized hardware—a powerful computing gateway for the warehouse and a rugged mobile router for the fleet—logistics companies can build a powerful competitive advantage that delivers from the first mile to the last.

Further Reading:

A1: AGVs in a busy warehouse often operate in close proximity to each other and to human workers. A delay of even a few hundred milliseconds in a command from a central controller (due to network latency) can be the difference between a smooth, efficient turn and a costly collision that shuts down an entire section of the warehouse. Edge control minimizes this latency.

A2: Telematics is the technology of sending, receiving, and storing information relating to remote objects, such as vehicles, via telecommunication devices. In fleet management, this typically includes data like vehicle location, speed, engine diagnostics (from the CAN bus), fuel consumption, and driver behavior.

A3: A vehicle-grade router is specifically designed to survive the harsh mobile environment. Key features include an E-Mark certification for automotive use, a wide voltage input to handle unstable vehicle power, resistance to extreme shock and vibration, and software features like ignition sensing to manage power states.