Choosing Your Hardware: Edge Gateway vs. Industrial PC for Edge Control

|

|

Time to read 4 min

|

|

Time to read 4 min

When choosing the hardware for edge control, engineers often face a critical decision: build a system around a powerful Industrial PC (IPC), or deploy a purpose-built, integrated Edge Gateway? This guide provides a direct Edge Gateway vs. IPC comparison. While an IPC offers raw computing power, we'll demonstrate why an integrated Edge Gateway is the superior choice for most edge control applications due to its all-in-one reliability, lower Total Cost of Ownership (TCO), and faster time-to-market.

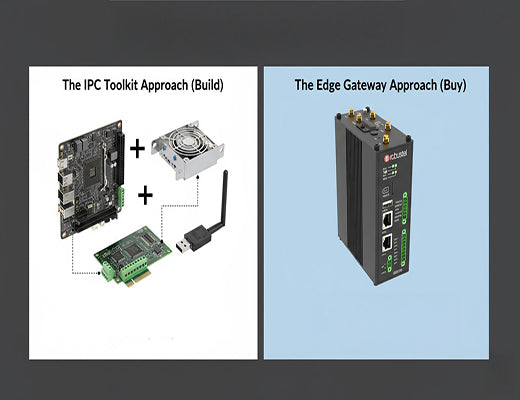

The choice between an Edge Gateway and an IPC is a choice between an integrated "instrument" and a component-based "toolkit."

Industrial PCs (IPCs) are powerful but complex. They require you to integrate separate components for connectivity and I/O, which increases cost, complexity, and potential points of failure.

Edge Gateways are purpose-built for connectivity and control. They integrate processing, industrial I/O, and cellular connectivity into a single, rugged, pre-certified device.

For most edge control applications, an integrated Edge Gateway like the EG5120 provides a more reliable, cost-effective, and faster path from concept to deployment.

You're designing the hardware for your new real-time quality inspection system. You need enough processing power to run an AI model, the right interfaces to connect to a PLC, and a reliable way to get it all online. The debate in the engineering room begins: should we use a powerful Industrial PC (IPC) as the brain, or a more specialized Edge Gateway?

It's a classic "build vs. buy" dilemma. The temptation of an IPC's raw power is strong, but it's a path filled with hidden complexities.

Let's be clear: for the demanding and specific task of edge control, the right choice of hardware is not just about the CPU specs. It's about total system reliability, cost, and speed of deployment.

An IPC is essentially a ruggedized desktop computer. It's a powerful and flexible toolkit that allows you to build almost anything.

An Edge Gateway is not a general-purpose computer; it's a purpose-built instrument designed specifically for industrial connectivity and control.

The 'aha!' moment for most architects is realizing that an integrated approach solves all the problems inherent in a component-based system.

The choice of hardware for your edge control system is a strategic one. While the raw power of an IPC is tempting, the practical realities of industrial deployments—reliability, cost, and speed—point to a clear winner.

For the specific and demanding task of real-time industrial automation, the integrated, purpose-built Edge Gateway is the superior choice. It is the professional instrument designed to do the job with maximum reliability and efficiency, allowing you to focus on your application, not on building and debugging your hardware.

Further Reading:

What is Edge Control? The Future of Real-Time Industrial AutomationThe Core Hardware for Edge Control: From CPU/NPU to Industrial I/OEdge Control vs. PLC: A Guide to Modern Automation Architecture

A1: An IPC might be a better choice for highly specialized, computationally massive applications that are not connectivity-focused. For example, a high-end medical imaging device or a complex, multi-camera machine vision system that requires a powerful x86 processor and specialized PCI-e cards, and where cellular connectivity and remote management are not primary requirements.

A2: Historically, x86 processors offered higher raw performance, while ARM processors were more power-efficient. However, modern, high-end ARM processors (like the quad-core Cortex-A53 in the EG5120) are incredibly powerful and more than capable of handling the vast majority of industrial control and AI inference tasks, offering the best balance of performance and power efficiency for the edge.

A3: An IPC typically runs a standard Windows or desktop Linux OS, giving you a familiar environment but requiring you to manage the OS yourself. A professional edge gateway runs a hardened, secure, and purpose-built embedded Linux OS (like RobustOS Pro). Critically, it comes with a built-in Docker engine and integrates with a cloud platform for secure, remote OTA software updates—a feature you would have to build yourself for an IPC.