A Deep Dive into DIN-Rail Mounting for Industrial Hardware

|

|

Time to read 5 min

|

|

Time to read 5 min

DIN-rail mounting is a universal standard for installing industrial control hardware, such as routers, PLCs, and power supplies, inside equipment enclosures. It utilizes a standardized metal rail onto which devices can be quickly and securely snapped. This method dramatically speeds up installation, improves organization and serviceability, and is a key feature of any professionally designed industrial hardware.

DIN-rail mounting is the global standard for installing hardware in industrial control panels, ensuring interoperability between different manufacturers' devices.

Compared to traditional panel mounting (drilling and screwing), it saves significant time and cost during both initial installation and later maintenance.

A well-organized DIN-rail layout improves airflow, serviceability, and even electrical safety and EMC performance through proper grounding.

Choosing hardware with a native DIN-rail clip is a hallmark of selecting a product that is truly designed for industrial environments.

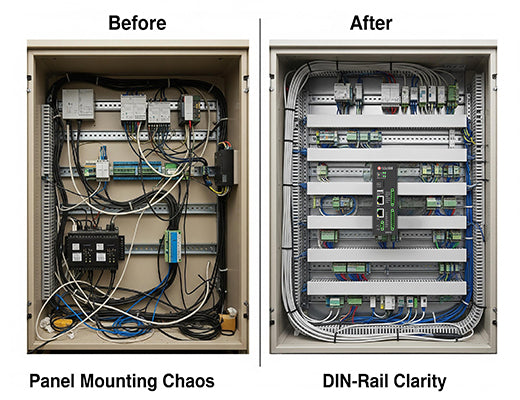

I've seen inside hundreds of industrial control cabinets in my career. Some are a work of art: clean wiring, logical layout, every component perfectly aligned. Others... well, they look like a "rat's nest" of wires, with devices screwed haphazardly onto the backplane wherever they fit. The difference? More often than not, it comes down to one simple, elegant piece of metal: the DIN rail.

For those new to the field, DIN-rail mounting might seem like a minor detail. But for seasoned engineers and panel builders, it’s the foundation of any professional installation. It’s the difference between a system that’s a nightmare to troubleshoot and one that’s clean, scalable, and easy to maintain.

Let's do a deep dive into this unsung hero of industrial automation and why it's a feature you should never overlook.

A DIN rail is simply a standardized metal rail that forms the backbone for mounting industrial hardware. The term "DIN" stands for Deutsches Institut für Normung, the German Institute for Standardization that originally published the specifications.

The most common type you'll encounter is the "top hat" style, or TS35 rail, which is 35mm wide. The magic is in the simplicity: industrial devices designed for this standard have a special spring-loaded clip on the back. You simply hook the device onto the top edge of the rail, push down, and it snaps into place with a satisfying click. No measuring, no drilling, no screws.

This is the big one for system integrators and panel builders. Manually measuring, marking, drilling, and tapping holes to mount each individual device on a backplane is incredibly time-consuming. DIN-rail mounting reduces that process to seconds. You mount one rail, then simply click your devices into place. This dramatically reduces labor costs and project timelines.

Because it’s a global standard, you can be confident that devices from different manufacturers will mount on the same rail. A Robustel industrial cellular router can sit perfectly next to a Siemens PLC, a Phoenix Contact power supply, and Weidmüller terminal blocks. This interoperability gives you the freedom to choose the best device for each function without worrying about physical compatibility.

All Robustel industrial products are designed with these principles in mind, featuring robust, easy-to-use mounting clips for professional installation.

It might seem like a simple piece of stamped metal, but DIN-rail mounting is a foundational element of professional, reliable, and maintainable industrial systems. The next time you're choosing an industrial cellular router or any other piece of hardware, pay attention to how it mounts. The presence of a well-designed DIN-rail clip is a clear sign that the manufacturer understands the real-world demands of the industrial environment.

Learn More in our main guide:

A1: "TS35" refers to the most common type of DIN rail. The "TS" stands for "Top-hat Section," describing its shape, and the "35" refers to its width in millimeters (35mm). There are other, less common sizes, but TS35 is the de facto standard for most control components.

A2: Yes, there are special adapters available that screw onto a non-compliant device and provide it with a DIN-rail clip. However, it's always preferable to choose hardware that has a native, integrated DIN-rail clip, as this provides a more secure and reliable mechanical connection.

A3: Yes, our entire portfolio of industrial routers and gateways is designed for professional installation. They all come with a built-in DIN-rail mounting clip and often include options for wall mounting as well.