The CNC Router Control Paradigm Shift: From Traditional to Edge Control

|

|

Time to read 4 min

|

|

Time to read 4 min

This guide explores the fundamental paradigm shift occurring in CNC router automation: the move from Traditional Control to Edge Control. While traditional CNC excels at deterministic execution of pre-programmed paths, edge control introduces a layer of real-time perception, data analysis, and adaptive intelligence directly at the machine. This isn't just an upgrade; it's a completely new way of thinking about how a CNC router operates, enabling unprecedented levels of efficiency, autonomy, and quality.

Traditional CNC Router Control is deterministic and blind: it perfectly executes a static G-code program, regardless of real-world variations.

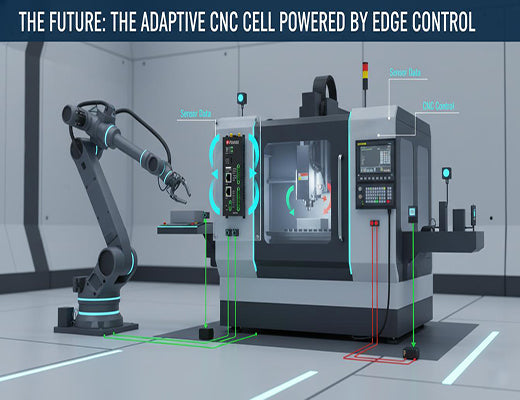

Edge Control is adaptive and perceptive: it uses real-time sensor data and local intelligence (on an edge gateway) to dynamically optimize the machine's actions.

This paradigm shift moves the CNC router from being a standalone executor to an intelligent, self-aware node in a larger data ecosystem.

The key difference lies in the introduction of a real-time, closed-loop "sense-decide-act" capability directly at the machine edge.

For decades, the core philosophy behind controlling a CNC router has remained largely unchanged. We create a perfect digital plan (G-code), and we rely on the machine's incredible precision to execute that plan flawlessly in the physical world. This deterministic model has been the bedrock of modern manufacturing. But what happens when the real world isn't perfect? When the material hardness varies slightly, or the tool begins to dull?

The traditional answer is: the plan fails. The part is scrapped, the tool breaks, the line stops. We are hitting the limits of purely deterministic control.

Let's be clear: a new paradigm is emerging. It's a shift from blind execution to intelligent adaptation. This new paradigm is edge control.

The traditional model is built on precision and repeatability.

Edge control doesn't replace the traditional controller; it enhances it by adding a layer of perception and real-time intelligence.

The 'aha!' moment is realizing this isn't just about adding a sensor. It's a fundamental change in where the "intelligence" resides and how decisions are made.

Feature |

Traditional CNC Control |

Edge Control for CNC Routers |

Decision Locus |

Pre-programmed (G-code) |

Real-time (Edge Gateway) |

Data Usage |

Minimal (Internal state only) |

Rich (Sensors + Controller Data) |

Adaptability |

None (Rigid Execution) |

High (Dynamic Optimization) |

Control Loop |

Open (Position only) |

Closed (Process-aware) |

Intelligence |

Deterministic |

Adaptive / AI-driven |

OT/IT |

Isolated OT |

Bridged OT/IT |

The era of the CNC router as a purely deterministic executor is evolving. The future belongs to machines that can perceive their environment, analyze conditions in real-time, and intelligently adapt their actions. This paradigm shift, enabled by edge control, moves beyond simple automation towards true autonomy. By embracing this new architecture and leveraging powerful edge platforms, manufacturers can unlock unprecedented levels of performance, quality, and resilience from their most critical production assets.

A1: No, quite the opposite! Edge control is designed to enhance and modernize your existing, reliable CNC router hardware by adding an external layer of intelligence. It leverages your current investment while adding powerful new capabilities.

A2: No. Cloud CNC typically refers to using cloud software for CAD/CAM or high-level production scheduling. Cloud control, as discussed previously, suffers from too much latency for the real-time adaptations that edge control enables. Edge control keeps the critical decision-making loop local to the machine.

A3: Edge control is a core enabling technology for Industry 4.0 and the emerging Industry 5.0. It provides the decentralized intelligence, data processing, and cyber-physical linkage required to build truly smart, interconnected, and autonomous manufacturing systems – making the concept of the "smart CNC router" a reality.