Step-by-Step: Connecting a Fanuc CNC Router via FOCAS Protocol

|

|

Time to read 6 min

|

|

Time to read 6 min

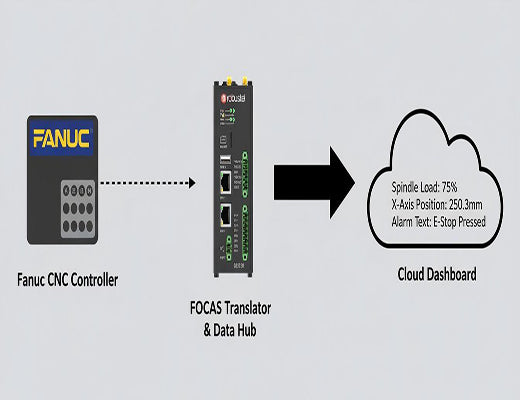

This step-by-step guide details how to connect your Fanuc CNC router and collect data using the powerful but complex Fanuc FOCAS protocol. We'll walk through the network setup, software requirements, and data acquisition logic needed to unlock the rich stream of real-time information available from Fanuc controllers. By leveraging an industrial edge gateway as the integration platform, you can simplify this process and reliably bridge your Fanuc CNC router to your modern monitoring and analytics systems.

The Fanuc FOCAS library/protocol is the standard way to access deep operational data from Fanuc CNC controllers over Ethernet.

Successfully implementing Fanuc FOCAS data collection requires careful network setup, the correct library versions, and application logic to make specific API calls.

An industrial edge gateway provides the ideal hardware platform: it offers the necessary Ethernet connectivity, runs the required software (often in a container), and securely bridges the data to IT systems.

Using a gateway with pre-built FOCAS drivers (like Robustel's Edge2Cloud Pro) can dramatically simplify the integration compared to building a custom application from scratch.

You're standing in front of a sophisticated CNC router powered by a Fanuc controller. You know it's a goldmine of data—real-time axis positions, spindle loads, alarm histories, tool offsets—data that could revolutionize your maintenance and efficiency. But how do you get it out? You've heard the term "FOCAS," but it seems complex and daunting.

Let's be clear: Fanuc FOCAS is powerful, and interfacing with it requires a methodical approach. But it's far from impossible, especially when you have the right platform acting as your intermediary. This guide will provide a clear, step-by-step path.

FOCAS (Fanuc Open CNC API Specifications) is a library provided by Fanuc that allows external applications to communicate with Fanuc CNC controllers over an Ethernet network. It's essentially a dictionary and a set of tools enabling your program to "ask" the CNC specific questions and get detailed answers. You don't just get basic status; you can potentially access hundreds of different data points.

Before you start, ensure you have:

This is the physical foundation.

The FOCAS communication logic needs to run somewhere. The edge gateway is the ideal place.

Your application (either configured in Edge2Cloud Pro or your custom container) needs to periodically make specific FOCAS function calls to read the desired data.

cnc_rdaxisdata(...) - To read current axis positions.cnc_rdspload(...) - To read the spindle load percentage.cnc_rdalmmsg(...) - To read current alarm messages.cnc_rdparam(...) - To read specific CNC parameters.Once the data is successfully read from the CNC router via FOCAS, the edge gateway performs its final critical task.

The 'aha!' moment is realizing the edge gateway solves multiple problems at once:

Connecting to a Fanuc CNC router using the FOCAS protocol opens up a universe of valuable, real-time data. While the protocol itself can be complex, leveraging a modern industrial edge gateway as the integration platform transforms this challenge into a manageable process. Whether using pre-built drivers or deploying your own containerized application, the edge gateway provides the secure, reliable, and powerful foundation needed to finally unlock the operational intelligence hidden within your Fanuc machines.

A1: Typically, yes. The FOCAS option needs to be enabled on the CNC controller itself, which is often a purchased software license from Fanuc. You may also need a separate development license if you plan to build your own custom application using their libraries.

A2: Most modern Fanuc controllers with an Ethernet port support FOCAS (e.g., Series 0i-MODEL D and later, Series 30i/31i/32i). However, the specific data points available can vary by controller model and software version. Always consult the Fanuc documentation for your specific controller.

A3: No, but it is often the most comprehensive. Some newer controllers also support standards like OPC UA. For simpler status monitoring, you might also use basic digital I/O or Modbus if supported. However, for deep, real-time operational data, FOCAS is Fanuc's primary mechanism.