Industrial Cellular Router for Smart Grid & Utility Applications

|

|

Time to read 5 min

|

|

Time to read 5 min

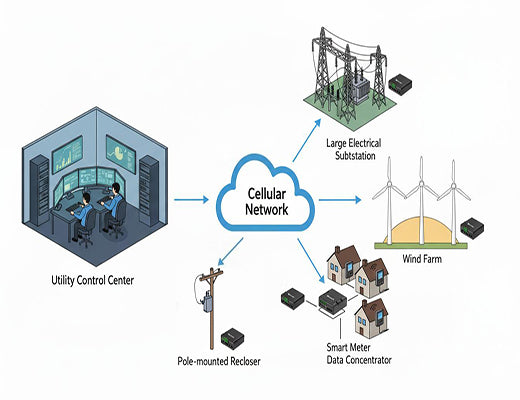

An industrial cellular router for smart grid and utility applications is the critical communication backbone for modernizing our energy and water infrastructure. These ruggedized devices provide the secure and highly reliable connectivity needed to remotely monitor and control critical assets like substation RTUs, electrical reclosers, and smart meter data concentrators, enabling a more efficient, resilient, and intelligent grid.

The smart grid relies on real-time, two-way communication, which is often best provided by a cellular network, especially in remote or hard-to-reach locations.

Reliability is paramount. Features like dual SIM failover and industrial-grade hardware are non-negotiable for utility applications where downtime is not an option.

Cybersecurity is a critical concern for public infrastructure. Industrial routers for utilities must have robust VPN capabilities and support for industry-specific security protocols.

Support for legacy utility protocols like DNP3 and IEC 60870-5-104 is often a key requirement for integrating with existing SCADA systems.

For a century, our electrical grid was a one-way street: power flowed from a central plant out to the consumers. But today, the grid is transforming into a dynamic, intelligent, two-way superhighway. With the rise of renewable energy, electric vehicles, and sophisticated automation, the "smart grid" is born.

But what makes a grid "smart"? The answer is data. A smart grid requires constant, real-time communication between thousands of points—from the substation down to the individual smart meter.

I've worked with numerous utility companies, and their biggest challenge is always the same: how do you reliably and securely connect assets that are spread across thousands of square miles, often in the harshest outdoor environments? Let's be clear: you don't do it by running thousands of miles of fiber. You do it with the right industrial cellular router for smart grid applications.

While fiber is great for core network backbones, cellular has become the technology of choice for connecting the vast number of distributed assets on the grid's edge. Here's why:

Not just any router can handle the demands of a public utility. The real 'aha!' moment for utility engineers is when they see a device that speaks their language—both in terms of hardware and software protocols.

Utility assets are exposed to the worst of the elements. A router used in a substation or a pole-top cabinet must have:

Downtime is not an option. A utility-grade router must have:

This is a critical differentiator. Your router needs to be a multilingual translator for the utility world.

An industrial cellular router for smart grid applications is a versatile tool used across the entire infrastructure.

The modernization of our utility infrastructure is one of the most important challenges of our time. Building a truly smart grid requires a communication network that is just as resilient, secure, and intelligent as the grid itself. The industrial cellular router for smart grid applications is the proven, purpose-built technology that makes this transformation possible, providing the reliable connectivity that keeps our lights on and our water flowing.

Learn More in our main guide:

A1: DNP3 (Distributed Network Protocol 3) is a set of communication protocols used between components in process automation systems. Its main use is in utilities such as electric and water companies. It was developed for communication between various types of data acquisition and control equipment.

A2: Utility networks are considered critical national infrastructure. A successful cyberattack could not only disrupt service to thousands of people but could also cause physical damage to expensive equipment or even threaten public safety. Therefore, using secure VPNs, firewalls, and access controls is absolutely mandatory.

A3: Yes, this is a key design feature. Industrial routers have a wide DC voltage input range (e.g., 9 to 36V DC), allowing them to be powered directly from the same DC power supply or battery backup system that runs the other equipment in the control cabinet, simplifying installation.