How to Build a Predictive Maintenance Solution with an IoT Edge Gateway

|

|

Time to read 6 min

|

|

Time to read 6 min

Unexpected machine downtime is one of the most costly problems in any industrial operation. But what if you could predict failures before they happen?

This guide explains how to build a modern predictive maintenance solution using an industrial IoT edge gateway. We’ll move beyond theory and provide a practical framework, covering how to use sensors to monitor machine health, process data at the edge for real-time anomaly detection, and create a robust alerting and data pipeline using MQTT.

Using the Robustel EG5120 as a real-world example, you'll learn how to leverage edge computing to reduce downtime, cut maintenance costs, and create smarter, more resilient factory operations.

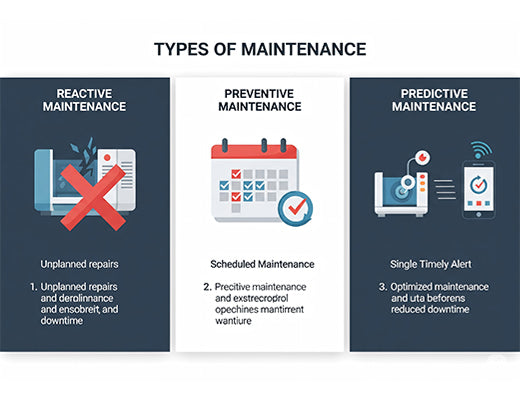

I've spent years talking to factory managers, and the story is almost always the same. Their biggest fear is the 3 AM phone call telling them a critical production line has gone down. The traditional "run-to-failure" maintenance model is reactive, expensive, and incredibly stressful. The next evolution, scheduled preventative maintenance, is better, but often results in replacing parts that are still perfectly good, wasting time and money.

The real game-changer is predictive maintenance (PdM) . This is the strategy of using real-time data to predict equipment failure before it occurs, allowing you to perform maintenance precisely when it's needed. But how do you actually build a predictive maintenance solution without a multi-million dollar budget? The answer lies at the edge, with a powerful Industrial IoT Edge Gateway . This guide will show you how.

You might think the best way to analyze machine health is to send all your sensor data to a powerful cloud AI. The problem is, for predictive maintenance, you need to catch anomalies the second they happen.

Sending terabytes of vibration and temperature data to the cloud is slow and incredibly expensive. The real "aha!" moment is realizing that an industrial IoT edge gateway can do the initial analysis on-site. According to a study by Deloitte, predictive maintenance can reduce breakdowns by up to 70% and lower maintenance costs by up to 25% . This is only possible with the low-latency processing that edge computing provides. Your gateway can analyze data in milliseconds, identify a deviation from the normal operating baseline, and trigger an immediate alert.

For a deeper look at this concept, read our guide: What is an Edge Gateway in IoT? A Comprehensive Guide?

You need to capture the right physical data. For machinery, this often means monitoring vibration and temperature. A multi-parameter sensor like the Robustel S6000U is ideal because a single device can provide:

3-axis vibration data (via an accelerometer) to detect imbalances or bearing wear.

Temperature readings to spot overheating.

Noise levels to identify acoustic anomalies. It communicates using the standard Modbus protocol, making integration easy.

This is the brain of your on-site operation. It needs to be powerful enough to run analytics and rugged enough for the factory floor. The Robustel EG5120 is a perfect fit, with its Quad-Core NXP i.MX 8 processor and Docker support .

This is where the magic happens. The gateway runs a flexible software stack to acquire, process, and transmit data.

Local Data Acquisition: Using tools like Node-RED to read data from the Modbus sensor.

Edge Processing: Running simple logic in Node-RED or more advanced anomaly detection algorithms in a custom Docker container (e.g., a Python script).

MQTT Broker: This is the central "post office" for your data. An MQTT broker (like Mosquitto) running on the gateway receives the processed data and makes it available for other services.

Cloud Integration via MQTT: The gateway then publishes the clean, processed data to a cloud-based MQTT broker. As explained by experts at HiveMQ, MQTT is the de facto standard for decoupling devices from applications in Industry 4.0 .

While real-time alerting happens at the edge, the cloud is used for long-term management and analysis. This includes:

Data Storage & Visualization: A cloud platform subscribes to the MQTT data and logs it into a time-series database like InfluxDB for visualization in Grafana.

Gateway Fleet Management: A platform like Robustel's RCMS is used for monitoring the gateway's health, deploying software updates, and managing the entire fleet of devices remotely.

First, you need to understand what "normal" looks like for your machine.

Connect your industrial sensor (like the S6000U) to your industrial IoT edge gateway (like the EG5120) via its RS485 port.

Use a tool like Node-RED on the gateway to read the vibration, temperature, and noise data from the sensor every second.

Log this data to a local or cloud-based InfluxDB database for a period of time (e.g., a week) while the machine is running under normal operating conditions.

Use Grafana to visualize this data. This dashboard now represents your machine's healthy "heartbeat."

Now, you use the gateway's intelligence to look for problems.

Analyze your baseline data to define thresholds for "abnormal" conditions (e.g., if vibration on the X-axis exceeds a certain G-force, or if the temperature rises 10°C above its normal average).

In your Node-RED flow or a custom Python script running in a Docker container, write simple logic: "IF current_vibration > threshold_vibration, THEN trigger_alarm." This entire detection process runs locally on the gateway , making it instantaneous.

When an anomaly is detected, you need to notify the right people immediately and log the event. The gateway is configured to:

Send an SMS alert directly to a maintenance engineer's phone for critical, immediate human intervention.

Publish an MQTT message with detailed alarm data to a central MQTT broker. From here, your cloud applications can subscribe to this topic to log the event in a maintenance system, trigger a work order, and update a live dashboard.

This multi-channel alerting ensures that nothing is missed.

Building a predictive maintenance solution is one of the most valuable investments an industrial operation can make, and it's more accessible than ever thanks to powerful industrial IoT edge gateways. By combining rugged sensors with an intelligent edge gateway like the Robustel EG5120, you can move away from a reactive maintenance model to a proactive, data-driven strategy. You no longer have to guess when a machine will fail; you can let the data tell you. This approach minimizes costly unplanned downtime, extends the life of your equipment, and represents a major step forward in creating a truly smart factory.

A1: Not for a basic, effective system. A simple threshold-based system ("if temperature > X, send alert") can be built with tools like Node-RED and provides immense value. More complex solutions using machine learning for anomaly detection are an advanced step but are also becoming more accessible with gateways that support containerization.

A2: For rotating machinery like motors, pumps, and fans, a vibration sensor (accelerometer) is typically the most important, as changes in vibration are often the earliest indicator of a mechanical failure. Temperature is also critically important.

A3: Yes, and that's a key advantage of this edge computing architecture. The industrial IoT edge gateway can perform all the data acquisition, analysis, and local alerting (e.g., triggering a warning light via its digital output) completely offline. It only needs an internet connection to send historical data to the cloud or for remote management via RCMS.