Getting Started with Predictive Maintenance: Using the S6000U for IoT Machine Monitoring

|

|

Time to read 5 min

|

|

Time to read 5 min

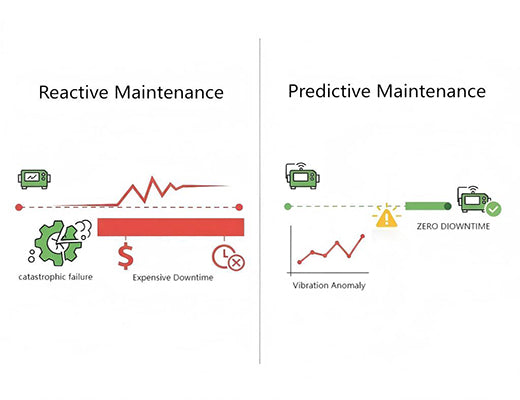

This guide provides a practical starting point for predictive maintenance (PdM) using IoT machine monitoring. We'll explain how an all-in-one industrial sensor with a built-in vibration monitoring sensor (accelerometer), like the Robustel S6000U, can be used to monitor the health of critical machinery like motors and pumps. By analyzing this data at the edge, you can detect the early signs of mechanical failure and shift from a costly, reactive maintenance strategy to a proactive, data-driven one.

IoT machine monitoring is the foundation of any modern predictive maintenance (PdM) program, aiming to fix failures before they happen.

Vibration analysis is the most effective method for detecting developing mechanical faults (like bearing wear) in rotating machinery.

An all-in-one sensor hub like the S6000U simplifies deployment by providing a built-in 3-axis accelerometer for vibration monitoring, alongside other valuable sensors like temperature.

For PdM, edge computing is essential. High-frequency vibration data must be analyzed locally on an edge gateway to be practical and cost-effective.

I'll never forget the sound of a critical motor failing on a production line. It wasn't just the loud screech of metal; it was the sound of money evaporating. The entire line stopped. The cost of the downtime—lost production, idle workers, emergency repairs—ran into the tens of thousands of dollars per hour.

What if that machine could have told you it was in trouble, weeks before it failed?

Let's be clear: it can. Your machines are constantly communicating their state of health through subtle vibrations, temperatures, and sounds. You just need the right tools to listen. This is the core idea behind predictive maintenance iot, and this guide will show you how to get started.

The real 'aha!' moment is when you understand that every healthy machine has a unique vibration "fingerprint" or "baseline." It's the normal, healthy hum of operation. The goal of IoT machine monitoring is to continuously listen to this hum and detect when it changes. A subtle increase in vibration can be the earliest indicator of a developing problem, such as:

By detecting these anomalies early, you can schedule a repair at a convenient time, rather than waiting for a catastrophic failure.

High-frequency vibration data is far too large to stream to the cloud 24/7; it would be prohibitively expensive. This data must be processed locally.

Once the data is flowing to the gateway, you can begin the analysis.

This isn't just theory. A smart factory that implemented an edge-based monitoring solution for its industrial robots achieved staggering results:

These are the transformative results that a proactive, data-driven maintenance strategy delivers.

Getting started with predictive maintenance is no longer a complex, multi-million-dollar initiative reserved for massive corporations. By combining a versatile, all-in-one vibration monitoring sensor like the S6000U with a powerful and open edge gateway, any factory can take a practical, scalable, and high-ROI first step. It's the key to moving away from the constant stress of unplanned downtime and toward a smarter, more predictable, and more profitable operational model.

Learn more in our main guide:

A1: It's ideal for any type of rotating machinery where changes in mechanical health manifest as changes in vibration. This includes motors, pumps, fans, compressors, and gearboxes—the workhorses of most industrial facilities.

A2: Not to get started. You can begin by monitoring the overall vibration level (RMS) and setting simple thresholds. As your project matures, you can work with reliability experts or use modern AI tools to perform more advanced analysis (like FFT for frequency spectrum analysis) on the data you're collecting.

A3: Raw, high-frequency vibration data is massive. A single sensor can generate gigabytes of data per day. Streaming this over a cellular connection is not only prohibitively expensive but can also introduce latency that hides real-time issues. Edge computing is a practical requirement for any serious vibration analysis project.