A Practical Guide to IoT Remote Temperature Monitoring

|

|

Time to read 5 min

|

|

Time to read 5 min

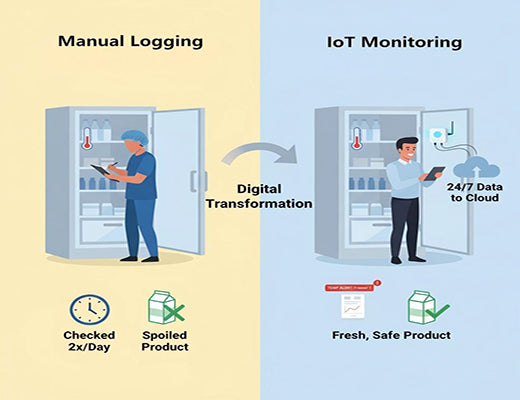

This practical guide to IoT remote temperature monitoring explains how to build a system to automatically track, log, and get alerts on critical temperatures for compliance and safety. We'll cover the essential components—from temperature sensor IoT devices to a reliable industrial gateway and a cloud platform—and show you how this modern approach replaces manual checks, prevents costly product spoilage, and provides complete peace of mind, 24/7.

An automated wireless temperature monitoring system replaces the manual, error-prone clipboard, ensuring accurate, around-the-clock data logging.

The key business benefits are ensuring regulatory compliance (e.g., HACCP for food safety), preventing thousands of dollars in lost inventory from equipment failure, and receiving instant SMS or email alerts the moment temperatures go out of range.

A complete system requires four key components: a temperature sensor/probe, a reliable industrial gateway for connectivity, a cloud platform for data storage, and an application for alerts and reporting.

A cellular-enabled gateway is the critical backbone, ensuring the system stays online and can send alerts even if the local Wi-Fi or power goes out.

I'll never forget the sinking feeling in a restaurant owner's stomach as he described coming into work on a Monday morning. The walk-in freezer had failed sometime over the weekend. He was met with a puddle on the floor and had to throw out over $10,000 worth of inventory. His twice-daily manual temperature checks on a clipboard couldn't protect him from a failure at 2 a.m. on a Saturday.

This is a story that plays out every day in restaurants, labs, and warehouses.

Let's be clear: this kind of catastrophic loss is now completely preventable. A simple, affordable IoT remote temperature monitoring system is the 24/7 insurance policy that protects your valuable, temperature-sensitive assets. This guide will show you how it works.

For years, the standard for temperature logging was a clipboard and a pen. This manual process is fundamentally flawed:

An automated wireless temperature monitoring system solves all three of these problems.

This is the "probe" that does the actual measuring. The type you choose depends on your application:

This is the heart and communication hub of your system. Its job is to collect the data from the sensor(s) and securely transmit it to the internet.

This is the final interface where you get value.

An IoT remote temperature monitoring system is no longer a complex or expensive luxury. It is an accessible and high-ROI investment for any business that depends on temperature-sensitive assets. It replaces manual labor with automated accuracy, swaps reactive panic for proactive alerts, and provides the digital audit trail needed for modern compliance. It's the simple, powerful tool that provides 24/7 peace of mind.

Learn more in our main guide:

A1: This is a critical feature. Your industrial gateway should be plugged into a battery backup or Uninterruptible Power Supply (UPS). Because the gateway uses its own cellular connection (independent of your local internet), it will remain online during a power outage and can be configured to send an immediate alert that the main power has been lost, in addition to any temperature alerts.

A2: Industrial-grade temperature sensors are highly accurate and reliable. They are often calibrated and can provide readings with an accuracy of within +/- 0.5°C or better, which is sufficient for even the most demanding medical and food safety applications.

A3: This is a key benefit of an automated system. The cloud platform securely logs every single temperature reading with a timestamp. From the dashboard, you can instantly generate and print a historical report for any time period an auditor requests, providing a perfect, unbroken data record.