4G LTE vs. 5G: Which is Right for Your Industrial IoT Application?

|

|

Time to read 5 min

|

|

Time to read 5 min

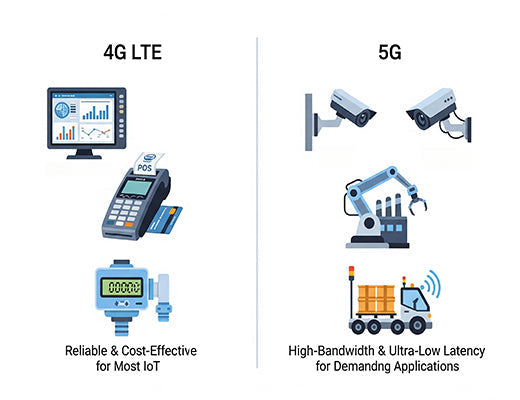

The choice between 4G vs. 5G for IoT isn't about which technology is "better," but which is the "right fit" for your specific industrial application.

4G LTE is the proven, cost-effective workhorse for the vast majority of current IIoT needs, like SCADA and remote monitoring.

5G is the high-performance specialist, essential for data-intensive applications like HD video and real-time robotics that demand massive bandwidth and ultra-low latency.

I’ve seen this happen in project planning meetings everywhere. The engineering team has a solid plan to connect remote assets using a reliable cellular router. Then, someone from marketing chimes in: "Shouldn't we be using 5G? We need to be future-proof!" Suddenly, a straightforward technical decision becomes a debate clouded by hype.

Let's cut through the noise. The move from 4G to 5G is significant, but it's not a simple upgrade like getting a new phone. In the industrial world, it’s a strategic decision with real consequences for your budget and performance. Choosing between 4G vs. 5G for your IoT project isn't about chasing the newest trend; it's about matching the right tool to the right job. This guide will give you a clear framework to make that decision.

When people talk about 4G vs. 5G for IoT , they usually start with speed. But for industrial applications, the most important differences are often latency and cost.

This is the most obvious difference. Think of bandwidth as the width of a highway.

This is the real game-changer for industrial control. Latency is the delay it takes for data to travel from the device to the network and back.

The reality on the factory floor is that budget always matters.

For the vast majority of IIoT applications today, an Industrial 4G Router is the smart, pragmatic choice. It provides the perfect balance of performance, reliability, and cost.

You should choose 4G LTE if your primary application involves:

You should invest in the power of an Industrial 5G Router when your application's success is directly tied to massive bandwidth or real-time responsiveness.

You need 5G if your application involves:

Feature |

Industrial 4G Router |

Industrial 5G Router |

Bandwidth |

Good (Mbps) |

Massive (Gbps) |

Latency |

Low (~30-100ms) |

Ultra-Low (<10ms) |

Cost |

Cost-Effective |

Premium |

Maturity |

Fully Mature & Global |

Evolving & Expanding |

Best For... |

SCADA, Telemetry, POS, Remote Monitoring |

HD Video, Robotics, Real-Time Control, Private Networks |

The choice between 4G vs. 5G for your IoT deployment shouldn't be driven by fear of missing out. It should be a pragmatic decision based on your specific needs.

For the vast majority of industrial applications today and in the coming years, 4G LTE provides a powerful, reliable, and financially sound foundation. It is the workhorse of the IIoT. 5G is the high-performance racehorse, a strategic investment for those specific, demanding applications where speed and responsiveness are everything.

By honestly assessing your application's requirements, you can confidently choose the right technology and ensure your project is a success from day one.

Learn More in our main guide:

A1: Yes, absolutely. All 5G industrial routers are built to be backward-compatible. If a 5G signal isn't available, the router will seamlessly connect to the best available 4G or LTE network, ensuring you always have a connection.

A2: Not at all. 4G LTE networks will continue to operate for many years, likely for another decade or more. They will coexist with 5G and will remain the primary connectivity layer for billions of IoT devices that don't require 5G's high performance.

A3: Yes. Private cellular networks are a rapidly growing field. Private 4G (often using CBRS in the US) is a very mature option for applications like logistics and push-to-talk. Private 5G is the next step for high-performance factory automation. The choice depends on your specific on-premise needs and budget.