CNC Router Communication Protocols Explained: RS232 to FOCAS

|

|

Time to read 5 min

|

|

Time to read 5 min

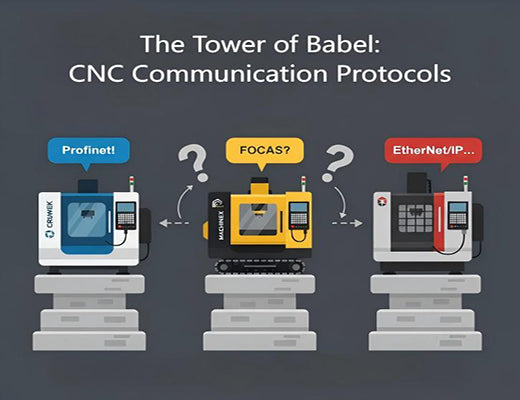

This guide provides an essential overview of the diverse CNC communication protocols you'll encounter when connecting a CNC router or machine tool. From legacy serial standards like RS232 to modern industrial Ethernet like EtherNet/IP and complex vendor-specific APIs like Fanuc FOCAS, understanding these "languages" is key to unlocking machine data. We'll explain the role of an edge gateway as a crucial "protocol translator," enabling seamless data acquisition from any CNC router.

CNC routers from different manufacturers speak different "languages" (protocols), creating integration challenges.

Common protocols range from simple Serial (RS232) for older machines to complex Industrial Ethernet (Profinet, EtherNet/IP) and vendor APIs ( Fanuc FOCAS).

An industrial edge gateway acts as a multi-lingual translator, understanding these diverse CNC communication protocols and converting the data into a standardized format.

This protocol conversion is the essential first step for any remote monitoring, OEE calculation, or predictive maintenance project involving your CNC router.

You're standing on a shop floor. To your left is a brand new German CNC router speaking Profinet. To your right is a reliable 15-year-old Japanese machine that only understands Fanuc FOCAS over Ethernet. In the corner is an older American model humming along, connected via a dusty RS232 serial port. Your mission: get real-time operational data from all three onto a single dashboard.

Welcome to the "Tower of Babel" that is modern manufacturing connectivity.

Let's be clear: machines don't magically talk to each other. They communicate using specific, often proprietary, protocols. Understanding the basics of these CNC communication protocols is the first step in bridging these data silos.

The diversity stems from a mix of historical evolution, technical choices, and vendor ecosystems:

As Ethernet became standard, industrial versions emerged, offering higher speeds and network capabilities.

Some manufacturers provide powerful Application Programming Interfaces (APIs) for deep data access.

The 'aha!' moment for any integrator is realizing you don't need a separate converter box for each protocol. A modern industrial edge gateway is the all-in-one solution.

A device like the Robustel EG5100 or EG5120, equipped with software like Edge2Cloud Pro, acts as a multi-lingual hub:

{"machine_id": "CNC01", "spindle_load": 75.5, "timestamp": "..."}).This architecture completely hides the complexity of the underlying protocols from your central monitoring and analytics applications.

Connecting a modern machine shop requires navigating a complex landscape of CNC communication protocols. Understanding these different "languages" is the first step. The second, and more crucial step, is deploying a powerful and versatile "translator"—an industrial edge gateway—that can bridge these disparate systems. By converting the cacophony of the factory floor into a single, coherent data stream, the edge gateway unlocks the true potential of your CNC router data and paves the way for a smarter, more connected operation.

A1: For modern industrial machines, IP-based protocols over Ethernet are standard. Depending on the manufacturer, you will most likely encounter Profinet (Siemens ecosystem), EtherNet/IP (Rockwell ecosystem), or a vendor-specific API like Fanuc FOCAS. Many machines also support the universal OPC UA standard.

A2: OPC UA (Open Platform Communications Unified Architecture) is a modern, secure, and platform-independent standard for industrial communication. It's designed to be the "universal translator" itself, enabling interoperability between different vendors' equipment. Many edge gateways and modern CNC controllers support OPC UA, making it a powerful tool for integration.

A3: Yes, a capable edge gateway can act bi-directionally. While the primary use case is data acquisition (reading from the CNC), it can also be used to write data back or send commands, enabling edge control applications (e.g., sending a feed rate override command based on sensor data). However, this requires careful implementation to ensure safety and avoid conflicting with the machine's primary control program.