What is IIoT? A Simple Guide to the Industrial Internet of Things

|

|

Time to read 5 min

|

|

Time to read 5 min

You've likely heard the term "Industrial Internet of Things" or "IIoT," but what does it actually mean? How is it different from the consumer IoT we hear about every day?

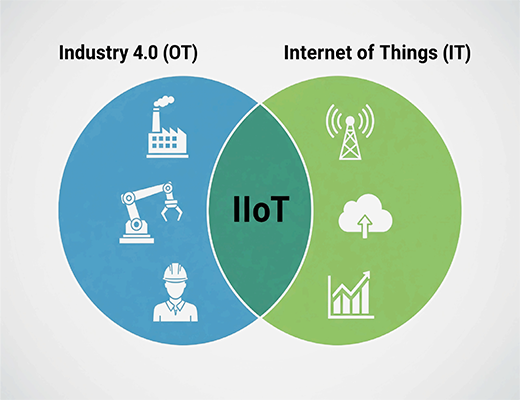

This guide uses a simple Venn diagram to clearly explain what is IIoT. We'll break down how IIoT represents the convergence of the physical, mechanical world of "Industry 4.0" and the digital, connected world of the "Internet of Things."

After reading, you will understand the core concepts of IIoT, its key components, and its transformative applications in modern industry.

Imagine a busy factory. A PLC (Programmable Logic Controller) is running a production line, a robotic arm is performing its tasks with precision, and an experienced engineer is making their rounds. This is the traditional industrial scene—efficient, but isolated. Now, what if that PLC, that robotic arm, and every sensor in the factory could "talk," sending their real-time status, health, and production data securely to the cloud for analysis?

That is the core idea of the Industrial Internet of Things (IIoT).

It's a revolution that's about more than just simple connectivity; it's about giving industrial equipment "intelligence" and a "voice." As the diagram you provided so perfectly illustrates, IIoT is the powerful intersection of two major technological waves:

This diagram is the perfect way to explain what is IIoT. Let's break it down:

This is a common point of confusion. While IIoT is a subset of IoT, they are worlds apart in their purpose, environment, and the stakes involved.

Feature |

Consumer IoT |

Industrial IoT (IIoT) |

Primary Goal |

Convenience, comfort, entertainment |

Efficiency, safety, productivity, profitability |

Environment |

Home, office (controlled environments) |

Factory, mine, outdoors (harsh, hazardous) |

The Stakes |

A failed smart bulb is an inconvenience. |

A failed PLC shuts down an entire production line. |

The Devices |

Smartwatches, smart speakers |

Industrial gateways, PLCs, high-precision sensors |

In short, when consumer IoT fails, it might ruin your day. When IIoT fails, it can cost millions of dollars and lead to serious safety incidents.

A typical IIoT solution is generally made up of four key parts:

Enough with the theory. Let's look at how IIoT creates value in the real world:

So, what is IIoT? It's much more than just connecting machines to the internet. It is a profound revolution in the industrial sector, with the core goal of using data from the physical world to make smarter business decisions. By combining reliable industrial equipment (OT) with powerful data analytics (IT), IIoT is helping companies around the globe become safer, more efficient, and more competitive.

A1: You can think of traditional SCADA systems as a precursor to IIoT. They focused on local monitoring and data acquisition. Modern IIoT architectures dramatically expand SCADA's capabilities with edge and cloud platforms, enabling larger-scale, more intelligent data analysis and remote management.

A2: IIoT can improve safety in many ways. For example, sensors can monitor for hazardous gas leaks, equipment overheating, or abnormal vibrations and automatically trigger an alarm or a shutdown procedure. It can also reduce the number of times personnel need to enter hazardous areas through remote monitoring.

A3: To start an IIoT project, you first need a clear business problem you want to solve (e.g., "reduce machine downtime"). Then, you'll need a foundational solution that typically includes sensors, a reliable industrial IoT gateway to collect and process the data, a connectivity plan, and a cloud platform for visualization and analysis.