The TCO of Edge Computing: A Guide to DIY vs. Commercial Gateways

|

|

Time to read 5 min

|

|

Time to read 5 min

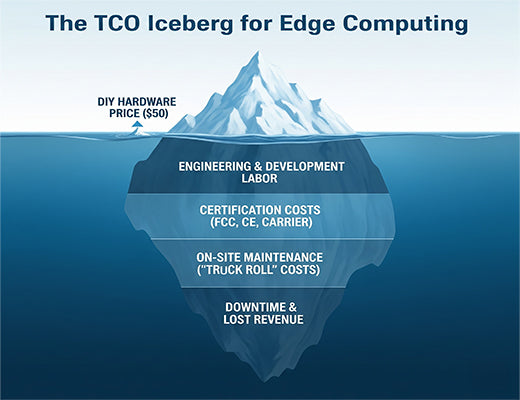

When evaluating the TCO of edge computing, many projects make a critical mistake: they compare the price of a $50 single-board computer to a professional industrial gateway.

This guide breaks down the TCO "iceberg," revealing the massive hidden costs of a DIY approach in engineering labor, certifications, long-term maintenance, and scalability.

While a DIY vs. commercial edge gateway debate seems to favor DIY on price, a true TCO analysis almost always proves that an integrated commercial platform is the faster, more reliable, and ultimately cheaper solution for any serious deployment.

I've been in countless project kickoff meetings where someone holds up a Raspberry Pi and says, "Why should we pay thousands for a commercial edge gateway when we can build our own with this for fifty bucks?" On the surface, it's a tempting and logical question.

But it's a question that completely misses the real picture. It's a calculation that only sees the tip of a very large, very expensive iceberg.

Let's be clear: the true cost of a solution isn't what you pay for the hardware; it's what you pay over the entire lifecycle of your project. When you run the numbers on the TCO of edge computing, the "cheap" DIY route often ends up being the most expensive decision you can make. This guide will show you why.

When you choose a commercial gateway, you're buying a finished product. When you choose the DIY route, you're starting a complex and costly internal product development project. Here are the massive hidden costs lurking below the surface.

Let's look at a simplified comparison for a deployment of 100 units.

Cost Category |

DIY (e.g., Raspberry Pi based) |

Commercial Gateway (e.g., EG5120) |

Initial Hardware |

~$200/unit (incl. all parts) = $20,000 |

~$1,000/unit = $100,000 |

Development & Integration |

2 Engineers x 12 months = ~$300,000+ |

Included |

Certifications |

FCC, CE, Carrier Certs = ~$50,000 - $100,000+ |

Included |

Cloud Management Platform |

Build from scratch = ~$100,000+ |

Included (e.g., free RCMS tier) |

Year 1 Estimated Cost |

~$470,000+ |

~$100,000 |

The real 'aha!' moment is seeing that even with a conservative estimate, the DIY path can be over 4 times more expensive in the first year alone, before you even factor in the ongoing maintenance costs.

A DIY solution that seems manageable for a 10-device pilot can become a logistical and financial nightmare at scale. Manually configuring and updating 1,000 devices is impossible. Without a purpose-built fleet management platform that supports features like Zero-Touch Provisioning, your operational costs will explode, and your project will fail under its own weight. This is the "pilot and scale fallacy" that sinks many internal projects.

While the appeal of building a DIY edge gateway is understandable, a thorough analysis of the Total Cost of Ownership for edge computing tells a clear story. The upfront cost is a ilusion. The hidden costs of development, certification, maintenance, and management make the DIY path significantly more expensive and slower.

A commercial industrial edge gateway is more than just hardware; it's an integrated, pre-certified, and professionally managed platform. It allows your team to focus on what they do best—building your unique application—not on the plumbing of hardware and infrastructure. It's the fastest, most reliable, and, ultimately, the most financially sound path to a successful, scalable deployment.

Yes, the open-source software itself is free. However, the expert engineering labor required to integrate, harden, test, secure, and maintain that software for a decade-long industrial product lifecycle is the single most expensive part of a DIY project.

It's significant. A typical, fully internal IoT project can take 18 to 24 months to launch. By using a mature commercial platform, that time can often be cut to under 12 months, allowing you to get to market a full year or more ahead of your competition.

A DIY approach is excellent for one-off internal prototypes, academic research, or non-critical hobbyist projects where time-to-market, long-term reliability, and scalability are not primary concerns. For any commercial or mission-critical deployment, a commercial gateway is the professional choice.