How to Implement Predictive Maintenance with Edge Computing

|

|

Time to read 6 min

|

|

Time to read 6 min

Implementing predictive maintenance with edge computing is a high-impact, practical strategy to dramatically reduce unplanned downtime in industrial operations. This guide provides a simple 4-step framework for getting started. The process involves connecting sensors (for vibration, temperature, etc.) to a powerful on-site IoT Edge Gateway, which analyzes the data locally and in real-time to detect anomalies that signal a future failure. This allows you to schedule maintenance proactively, turning a potential catastrophe into a routine repair.

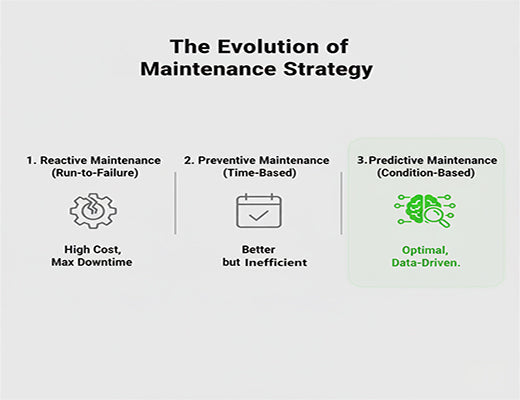

Predictive Maintenance (PdM) uses real-time equipment data to predict failures before they happen, shifting your team from a reactive "break-fix" model to a proactive, data-driven one.

Edge computing is the key that makes PdM practical and affordable, allowing for real-time, on-site data analysis without the massive costs and latency of a cloud-only approach.

The core process is straightforward: 1. Connect Sensors, 2. Process Data on an Edge Gateway, 3. Detect Anomalies, and 4. Alert and Act.

Real-world results are significant: one smart factory used this approach to reduce unplanned robot downtime by 40% and boost Overall Equipment Effectiveness (OEE) by 15%.

I'll never forget the sound of a critical motor failing on a production line. It wasn't just the loud screech of metal; it was the sound of money evaporating. The entire line stopped. The cost of the downtime—lost production, idle workers, emergency repairs—ran into the tens of thousands of dollars per hour.

The most frustrating part for the factory manager? His team had serviced that motor just two weeks prior. They were following a traditional, time-based maintenance schedule. But the schedule can't predict a random bearing failure.

Let's be clear: in a competitive manufacturing landscape, you can't afford to be reactive. You need to know a failure is coming before it happens. This is the promise of predictive maintenance with edge computing, and it's more accessible today than ever before.

For years, the concept of predictive maintenance was a dream for many. The challenge was data. A motor's vibration signature might need to be sampled thousands of times per second to detect a subtle anomaly. Sending this massive, high-frequency stream of data to the cloud 24/7 is often technically impractical and financially impossible due to cellular data costs.

This is where edge computing changes the game. By placing a powerful computer—an IoT Edge Gateway—right next to the machine, you can analyze all that data locally and in real-time. The gateway becomes your on-site data scientist, constantly watching the machine's health and only sending a small, simple alert to the cloud when it detects a problem.

You can't predict what you can't measure. The first step is to attach sensors to your critical asset to capture its operational data. For rotating machinery like motors, pumps, and gearboxes, the most valuable data points are:

An all-in-one industrial sensor, like the Robustel S6000U, can capture all of these key metrics in a single, easy-to-deploy device.

Once the data is on the gateway, you need to analyze it. You can start simple and grow from there:

When the edge gateway detects an anomaly, it triggers the final step. It sends a small, targeted alert packet over the network to your central management platform (like RCMS) or SCADA system. Your maintenance team receives a notification like, "Motor 7 shows early-stage bearing wear. Schedule inspection." This allows you to turn an unplanned, catastrophic failure into a planned, routine maintenance task.

This isn't just theory. A forward-thinking smart factory deployed this exact strategy to monitor its fleet of industrial robotic arms.

This is the power of moving intelligence to the edge.

Implementing predictive maintenance with edge computing is one of the highest-ROI projects a modern industrial enterprise can undertake. It fundamentally changes your maintenance model from expensive, reactive firefighting to a data-driven, proactive, and far more profitable strategy.

With the accessibility of modern all-in-one sensors and powerful, easy-to-use edge gateways, this transformative capability is no longer reserved for massive corporations. It's a practical, scalable solution that you can start deploying today, one critical asset at a time.

Learn more in our main guide:

A1: No, not at all. You can achieve significant value by starting with simple, threshold-based alerts (e.g., "alert me if vibration exceeds X"). As you gather more data, you can then work with specialists or use modern automated machine learning (AutoML) tools to develop more sophisticated AI models.

A2: For rotating machinery like motors, pumps, fans, and gearboxes, vibration analysis is universally considered the most effective data source for detecting mechanical faults like bearing wear, imbalance, and misalignment. Temperature is a close second.

A3: The best way to start is with a proof-of-concept on a single, non-critical but important machine. An "IIoT Starter Kit" that bundles an industrial sensor and a pre-configured edge gateway is a great way to get from unboxing to seeing your first actionable data in a matter of hours, not months.