How Does a CNC Router Work? A Simple Explanation

|

|

Time to read 5 min

|

|

Time to read 5 min

Ever wondered how a CNC router works its magic, transforming a block of wood or plastic into a complex shape with seemingly effortless precision? This simple explanation breaks down the core components and process. At its heart, a CNC router uses a computer controller to read digital instructions (G-code) and translate them into precise, coordinated movements of its cutting tool along different axes, effectively automating the work of a master craftsman.

A CNC router works by translating a digital design file into physical movements using a computer controller, motors, and mechanical axes.

The process relies on G-code, a specific instruction language that tells the machine exactly where and how fast to move.

The CNC controller is the "brain," interpreting the G-code and sending electrical signals to the motors.

Motors (Stepper or Servo) act as the "muscles," precisely turning these signals into physical movement along the X, Y, and Z axes.

Watching a CNC router glide effortlessly across a piece of material, carving out intricate details, can feel like watching magic. But behind the apparent sorcery lies a beautifully logical system of digital instructions and precise mechanical movements. How does it actually translate a file on a computer into a physical object?

Let's be clear: the fundamental principle is surprisingly straightforward. It's about giving a machine the ability to read a map and follow directions with superhuman accuracy. This guide will simply explain how a CNC router works.

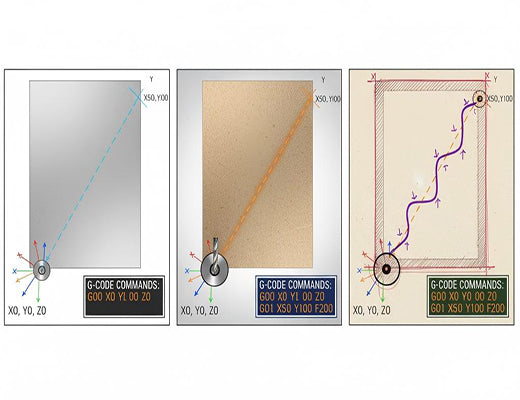

As we discussed in our guide to CNC Router Software, the journey starts with a digital design (CAD) which is then translated into a set of specific instructions called G-code (CAM). This G-code file is the "map" that the CNC router will follow. It contains commands like:

G01 X50 Y100: Move the tool in a straight line to position X=50mm, Y=100mm.S18000: Set the spindle speed to 18,000 RPM.M03: Turn the spindle on (clockwise).The CNC router's job is to read this map and physically execute these movements.

To understand the movement, you need to know the key players:

This is where the digital instructions meet the physical hardware.

So, how does a CNC router work in sequence?

G01 X50 Y100).Industrial CNC router controllers often feature network connectivity, allowing G-code transfer, remote monitoring, and even edge control integration via gateways like the EG5120.

At its heart, how a CNC router works is a remarkable feat of translation. It translates abstract digital coordinates and commands from a G-code file into precise, synchronized physical movements of its axes and spindle. It is this accurate and repeatable translation, orchestrated by the CNC controller and executed by the motors, that allows these incredible machines to automate complex cutting tasks with unparalleled precision.

A1: An axis refers to a direction of movement. A standard 3-axis CNC router moves along the linear X (left/right), Y (forward/back), and Z (up/down) axes. More advanced machines might have rotational axes (A, B, or C) for more complex, multi-sided machining.

A2: Stepper motors move in fixed steps based on received pulses (open-loop). They are simpler and cheaper but can lose steps (positional errors) if overloaded. Servo motors use an encoder to constantly report their position back to the controller (closed-loop), allowing for higher speeds, greater accuracy, and the ability to correct for errors. Servos are standard on industrial CNC router machines.

A3: G-code is the basic instruction language for CNC machines. Think of it like a very simple programming language made up of commands starting with 'G' (for preparatory commands, like movement type) and 'M' (for miscellaneous functions, like spindle on/off), followed by coordinates (X, Y, Z) and parameters (like Feed rate 'F' or Spindle speed 'S').