Edge Control Beyond One Protocol: Fusing LoRaWAN and Modbus with the R1520LG

|

|

Time to read 4 min

|

|

Time to read 4 min

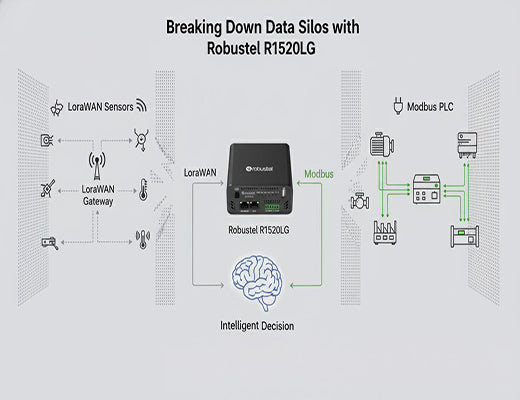

This guide explores an advanced application of edge control: multi-protocol data fusion. We'll explain how a traditional control system is often limited to a single protocol, creating data silos. By using a hybrid gateway like the Robustel R1520LG, you can simultaneously collect data from a wide-area wireless LoRaWAN network and a local wired Modbus network. This guide shows how to fuse this data at the edge to make smarter, more contextual decisions, enabling a new level of intelligent industrial automation.

True industrial intelligence often requires correlating data from multiple, different types of sensor networks.

The R1520LG is a unique device that acts as both a LoRaWAN gateway and a Modbus master, allowing it to "speak two languages" at once.

This protocol fusion capability is the key to building more sophisticated edge control logic that is based on a richer, more complete view of the operational environment.

By processing and fusing this data locally, you can create complex, autonomous control loops that are impossible with siloed, single-protocol systems.

I was with a system integrator designing a smart irrigation system for a large agricultural facility. They had wireless LoRaWAN soil moisture sensors spread across the fields—perfect for long-range, low-power sensing. They also had a powerful, wired irrigation pump controlled by a PLC that spoke Modbus.

Their problem? The two systems couldn't talk to each other. Their "brain" was in the cloud. The system had to send the soil data up to the cloud, have the cloud make a decision, and then send a command back down to the pump. It was slow, and it was completely dependent on a stable internet connection.

What if one device could listen to both conversations and make the decision right there in the field? Let's be clear: it can. This is the power of multi-protocol edge control.

The 'aha!' moment is when you realize your edge gateway can be a multilingual "fusion hub." A device like the Robustel R1520LG is uniquely designed for this role. Powered by RobustOS Pro (a Debian Linux environment), it can perform two tasks simultaneously:

This ability to natively understand both wireless, wide-area data and wired, local-area data is the key to building a more advanced edge control system.

Let's revisit the smart irrigation project.

The future of industrial automation lies in making smarter, more contextual decisions. Edge control provides the low-latency framework for this, but its intelligence is limited by the data it can see. By breaking down the silos between different network protocols and fusing the data at the edge, a hybrid gateway like the R1520LG provides a richer, more complete picture of the real world. This is the key to moving beyond simple, reactive logic and building truly intelligent and resilient edge control systems.

A1: Protocol fusion is a concept where an edge device collects data from two or more different communication protocols (like LoRaWAN and Modbus), normalizes it, and uses the combined, correlated data set to make a single, more intelligent control decision.

A2: While its hardware is optimized for LoRaWAN and serial protocols like Modbus, the R1520LG also has Ethernet ports. Because it runs a full Debian Linux OS, it has the software flexibility to communicate over a wide range of IP-based protocols as well, such as OPC UA or communicating with other devices via APIs.

A3: Yes, and this is the critical advantage. The entire "sense (LoRaWAN + Modbus) -> decide -> act" loop runs locally on the R1520LG. It does not need an active internet connection to perform its autonomous control functions, making it ideal for remote or mission-critical applications.