Optimizing Smart Energy Grids: Edge Computing for Smart Grid

|

|

Time to read 6 min

|

|

Time to read 6 min

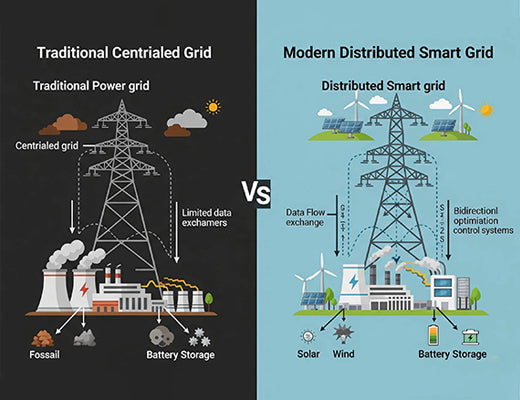

The modern energy grid is undergoing a massive transformation, moving from a centralized model to a distributed, complex ecosystem fueled by clean energy sources like solar and wind, and stabilized by energy storage systems. This shift presents enormous challenges in latency, reliability, and data management.

This guide explores the critical role of edge computing for smart grid optimization. We'll break down why the traditional cloud-only model is no longer sufficient and how deploying intelligence at the network edge with an industrial IoT edge gateway is the key to creating a more resilient, responsive, and efficient grid.

We'll cover key applications, from substation automation to renewable energy and energy storage integration, using the Robustel EG5120 as a real-world example.

I've spent a lot of time talking with engineers in the energy sector, and they all face a similar, daunting challenge. Our electrical grid, once a simple one-way street from power plant to consumer, is now a complex, multi-directional superhighway. With the rise of renewable energy sources like solar farms and wind turbines, the integration of Battery Energy Storage Systems (BESS) , plus electric vehicle charging stations and smart meters, the amount of data and the need for real-time control have exploded.

So, how do you manage a system where a cloud bank on one street can affect grid stability miles away? How do you react in milliseconds to a fault at a remote substation to prevent a wider blackout? Sending every byte of data to a centralized cloud for analysis is simply too slow and too risky. This is precisely why the conversation has shifted to edge computing for smart grid applications. The solution lies in deploying intelligence directly where it's needed, using a powerful Industrial IoT Edge Gateway .

Ultra-Low Latency: Enables real-time monitoring and autonomous control for grid stability and protection.

Increased Resilience: The grid can operate in localized segments even if the primary communication network goes down. The local edge gateway keeps running its logic.

Bandwidth & Cost Reduction: Processing high-frequency data from grid sensors (like Phasor Measurement Units - PMUs) locally and sending only key insights to the central SCADA system dramatically reduces data transmission costs.

Enhanced Security: An industrial IoT edge gateway acts as a secure buffer, protecting critical operational technology (OT) from external IT networks, a crucial aspect of what we cover in our guide to OT vs. IT Network Convergence .

This is the brain of the edge operation. It must be incredibly reliable and powerful. The Robustel EG5120 is a prime example, offering:

A powerful Quad-Core NXP i.MX 8 processor capable of running complex analytics and control logic.

A rugged, fanless design with a wide operating temperature range suitable for substation environments.

A suite of industrial interfaces, including RS232/RS485 for connecting to legacy RTUs and meters, and Gigabit Ethernet for modern IEDs.

The gateway must be a master translator. In the energy sector, this means speaking the language of power systems.

Industrial Protocols: Support for protocols like DNP3 and IEC 60870-5-101/104 is essential for communicating with RTUs (Remote Terminal Units) and IEDs (Intelligent Electronic Devices).

A Flexible OS: A Debian-based OS like RobustOS Pro provides the flexibility to run custom applications and Docker containers, allowing utilities to deploy their own proprietary control algorithms.

Secure Connectivity: A full suite of VPNs and a hardened firewall are critical for securing communication from the substation back to the control center.

This is a classic use case. An edge gateway installed in a substation can:

Collect data from multiple IEDs and RTUs using DNP3 or Modbus.

Run local automation logic to manage switchgear and transformers.

Provide secure remote access for technicians, reducing the need for site visits.

Filter and concentrate data before sending it to a central SCADA system.

With the rise of clean energy and distributed assets, the grid is no longer a one-way street. An industrial IoT edge gateway is essential for managing these complex resources.

Renewable Energy Integration: It can monitor the output of a solar farm or wind turbine in real-time.

Intelligent Energy Storage Management: This is where edge computing truly excels. An edge gateway can intelligently manage a Battery Energy Storage System (BESS) . It can execute complex algorithms locally to decide when to charge the battery (e.g., when renewable generation is high or electricity prices are low) and when to discharge it to the grid (e.g., during peak demand or to stabilize frequency). This real-time control is critical for maximizing the value of energy storage assets.

EV Charging Infrastructure: Manage smart charging stations, balancing the load on the local grid based on real-time conditions.

This is where speed is everything. An edge gateway can analyze data from sensors across a distribution line. If it detects a fault (like a downed power line), it can autonomously execute commands to reroute power and isolate the fault in milliseconds, minimizing the number of customers affected by an outage. This is something that simply cannot be done effectively from a centralized cloud.

The transition to a smarter, more resilient energy grid—one that heavily relies on intermittent clean energy and distributed energy storage —is impossible without intelligence at the edge. Edge computing for smart grid applications is no longer a future concept; it's a present-day necessity. By deploying powerful, secure, and flexible industrial IoT edge gateways like the Robustel EG5120, utilities and grid operators can enable the real-time monitoring, autonomous control, and secure communication needed to manage the complexity of the modern energy ecosystem. It's about making our grid not just more connected, but fundamentally smarter and more reliable.

A1: DNP3 and IEC 60870-5-104 are standard communication protocols used extensively in the electric utility industry. They are designed for reliable communication between control centers (SCADA masters) and remote devices like RTUs and IEDs. An industrial IoT edge gateway for the energy sector must support these protocols.

A2: Integrating intermittent clean energy sources like solar and wind requires fast, local control to manage fluctuations. An edge gateway can monitor renewable output and local demand in real-time, helping to make intelligent, sub-second decisions about charging or discharging energy storage systems to ensure grid stability.

A3: They are purpose-built for it. Devices like the EG5120 have a rugged, fanless metal enclosure, a wide operating temperature range (-40°C to +70°C), and undergo rigorous testing for electromagnetic compatibility (EMC) to ensure they can operate reliably amidst the high electrical noise of a substation.