Don't Wait for the Cloud: Why Edge Alarm Notifications are Essential for IIoT

|

|

Time to read 5 min

|

|

Time to read 5 min

In industrial operations, an alert that arrives seconds too late is as good as no alert at all.

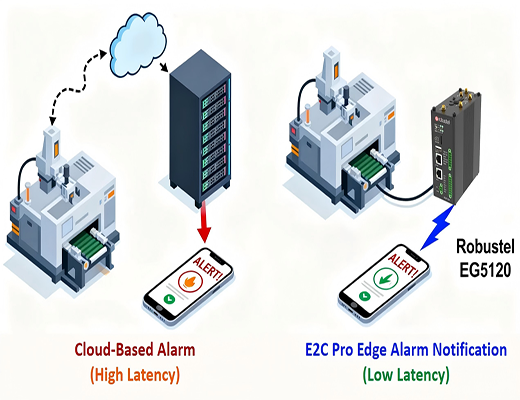

Traditional cloud-based alarm systems introduce critical delays that can lead to costly downtime or equipment damage.

This article explores why the future of industrial monitoring lies in edge alarm notification systems. We'll break down how Robustel's Edge2Cloud Pro software, running on edge computing gateways, provides a faster, more reliable, and infinitely more flexible solution by processing data and triggering alerts right where the action happens—at the machine level.

I've seen it happen more times than I can count. A critical pump's temperature starts to creep up on a remote site. The data is sent to the cloud, processed, and eventually, an alert is triggered. But by the time the email reaches the maintenance manager, the pump has already overheated, shutting down a key production line. The cost? Thousands of dollars in lost production, all because of a few seconds of network latency. It’s a frustratingly common scenario.

Let's be clear: in the world of Industrial IoT (IIoT), the cloud is often too far away for critical alerts. When you need an immediate response, you can't afford to wait for a round trip to a data center hundreds of miles away. So, what’s the alternative? You move the intelligence out of the cloud and to the edge. This is where a true edge alarm notification system becomes not just a nice-to-have, but an absolute game-changer.

The fundamental problem with cloud-based alarming is latency. The journey from your sensor to the cloud and back to your phone is fraught with potential delays: network congestion, server processing time, and internet outages. While this might be acceptable for monthly reports, it's a massive liability for critical industrial IoT alerts.

This is precisely the problem Robustel’s Edge2Cloud Pro software was built to solve. Running directly on a powerful edge computing gateway, it puts the entire alarm system—from data acquisition to notification dispatch—right next to your machinery. Data is processed locally, rules are evaluated in microseconds, and notifications are sent directly from the gateway itself. This isn't just an incremental improvement; it's a fundamental shift in how we think about industrial monitoring.

What makes an edge alarm notification system truly effective isn't just speed, but also intelligence and flexibility. In my experience, generic, one-size-fits-all alarm systems just don't cut it in complex industrial environments. Edge2Cloud Pro shines here by offering a deeply customizable and powerful rule engine.

The real "aha!" moment for many engineers is when they realize they can replicate complex, real-world logic without writing a single line of code. Edge2Cloud Pro’s rule engine is incredibly versatile.

equipment-fault, environmental-issue, or supply-chain-alert. This makes diagnostics and reporting infinitely more meaningful.

Because Edge2Cloud Pro lives on the edge, it can send notifications directly, bypassing the cloud bottleneck entirely. This has two massive advantages. First, it’s lightning-fast. Second, it's more reliable. What if the site's primary internet connection goes down? A cloud platform is rendered useless, but the Edge2Cloud Pro gateway can still send an alert via its cellular (SMS) connection.

It supports multiple channels, including:

Furthermore, you can create custom notification templates. These templates can pull in system variables like the device name, the specific value that triggered the alarm, the time, and the alarm's name. The result? The person on call gets a message that says, “High Pressure Alarm on Pump-03: Value 152 PSI at 10:32 AM,” not a generic, cryptic code.

Here’s where an edge-based system truly distances itself from the cloud. An alert is good, but an automated action is better. Because Edge2Cloud Pro is part of a comprehensive edge computing platform, an alarm can be more than just a notification—it can be a trigger.

Let's go back to our overheating pump scenario. With Edge2Cloud Pro, you can create a rule: if the temperature exceeds 90°C, not only should it send an SMS to the maintenance team, but it should also simultaneously trigger a command to increase the speed of the cooling fan connected to the same gateway. The problem is actively being mitigated before a human even has to intervene. This fusion of real-time PLC alarm system monitoring and automated control is the cornerstone of a truly smart industrial operation.

Adopting an edge computing alerts strategy with Edge2Cloud Pro delivers tangible benefits that directly impact your bottom line and operational resilience.

A1: Absolutely. This is one of its biggest strengths. If the primary internet fails, the gateway can use its cellular module to send notifications via SMS, ensuring alerts always get through.

A2: You can monitor virtually any industrial device. Edge2Cloud Pro supports over a hundred mainstream industrial protocols, including Modbus, OPC UA, Siemens S7, and many others, allowing you to connect to PLCs, sensors, smart meters, and more.

A3: No. All alarm rules, notification templates, and logic are configured through a user-friendly web interface. For more complex workflows, it integrates Node-RED, a low-code, visual programming tool that uses a drag-and-drop interface.