Connectivity Options for Your CNC Router: Wired Ethernet vs. Wi-Fi vs. Cellular

|

|

Time to read 5 min

|

|

Time to read 5 min

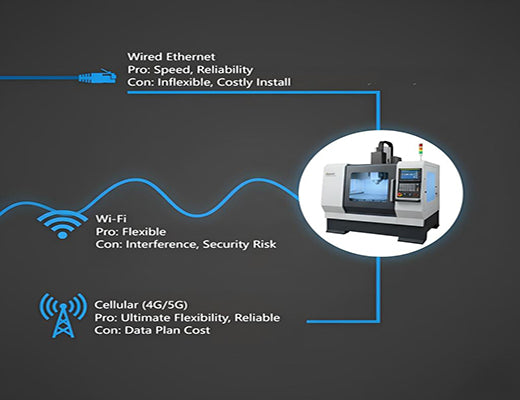

Choosing the right connectivity option for your CNC router is a critical decision that impacts reliability, cost, and flexibility. This guide compares the three main methods: traditional Wired Ethernet, convenient Wi-Fi, and versatile Cellular (4G/5G). We'll break down the pros and cons of each in an industrial setting, helping you determine the best fit for your specific machine shop environment and operational needs.

There are three primary CNC connectivity options: Wired Ethernet, Wi-Fi, and Cellular (4G/5G).

Wired Ethernet offers the highest speed and reliability but lacks flexibility and can be costly to install.

Wi-Fi offers flexibility but can suffer from interference, security risks, and lower reliability in harsh industrial environments.

Cellular (4G/5G), using an industrial router, provides the ultimate flexibility, rapid deployment, and network path diversity, making it ideal for many modern shop floor scenarios.

You've made the strategic decision. You're ready to unlock the data from your CNC router and integrate it into your smart factory ecosystem. Now comes the practical question: how do you physically establish that connection? Do you run a new network cable? Can you just use the shop's existing Wi-Fi? Or is a dedicated cellular connection the way to go?

Let's be clear: there's no single "best" answer for every situation. Each connectivity method has its own strengths and weaknesses, especially when dealing with the demanding environment of a machine shop. Understanding these trade-offs is crucial.

This is the classic, tried-and-true method for network connectivity.

Leveraging your existing wireless network seems like an easy solution.

Using a dedicated cellular connection via an industrial router offers a compelling blend of reliability and flexibility.

The 'aha!' moment is realizing the choice depends on your specific context.

Scenario |

Best Fit |

Why |

New Factory, Stable Layout |

Wired Ethernet |

Highest reliability & speed, cost integrated into initial build. |

Existing Factory, Need Flexibility |

Wi-Fi (Carefully!) or Cellular |

Wi-Fi if coverage is excellent & secure; Cellular otherwise. |

Remote/Temporary Machine |

Cellular (4G/5G) |

Only viable option, instant deployment. |

Need Backup Connectivity |

Cellular (4G/5G) |

Provides true path diversity for maximum uptime. |

There are multiple valid CNC connectivity options, each with distinct advantages. While wired Ethernet remains the gold standard for fixed installations where feasible, the flexibility and resilience of cellular connectivity, delivered through a robust industrial cellular router, make it an increasingly compelling choice for modern, dynamic manufacturing environments. By carefully evaluating your shop floor layout, reliability requirements, and budget, you can select the connectivity strategy that best empowers your CNC router to become a truly smart, connected asset.

A1: It can be, but requires careful planning. Industrial environments are challenging for Wi-Fi due to interference. You need a professionally designed, robust Wi-Fi network with excellent coverage and strong security protocols. For critical data or control applications, many engineers still prefer the guaranteed reliability of wired Ethernet or a dedicated cellular link.

A2: For basic monitoring (status, alarms, cycle times), data usage is generally very low, often just megabytes per month, making cellular M2M/IoT plans very affordable. If you plan to transfer large program files frequently or stream high-frequency sensor data, usage will be higher.

A3: It's strongly discouraged for professional use. USB dongles are consumer-grade, lack the environmental hardening needed for the shop floor, often have unreliable connectivity, lack critical security features like VPNs, and cannot be remotely managed effectively. An industrial cellular router is a purpose-built, reliable solution.