The Software Behind the Cut: Understanding CAD, CAM, and Control for Your CNC Router

|

|

Time to read 5 min

|

|

Time to read 5 min

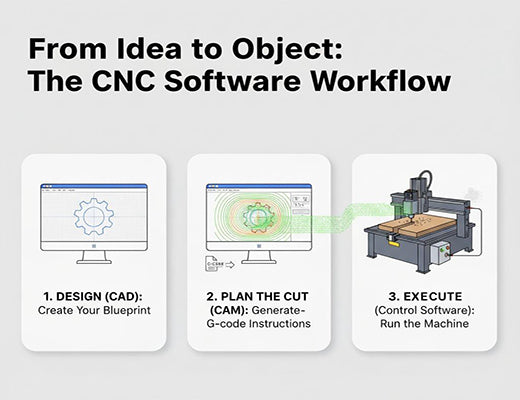

A CNC router is a powerful machine, but it's only as smart as the software that drives it. This beginner's guide breaks down the essential three-part software workflow behind every cut: CAD (Computer-Aided Design) to create your design, CAM (Computer-Aided Manufacturing) to plan the cutting paths, and the Control Software that reads these instructions and physically moves the CNC router. Understanding this process is key to unlocking your machine's potential.

Operating a CNC router involves a three-stage software process: CAD -> CAM -> Control.

CAD software is where you create the digital 2D or 3D design of the part you want to make.

CAM software takes your CAD design and generates the specific toolpaths (cutting instructions) in a language the machine understands, called G-code.

Control Software (often running on the machine itself or a connected PC) interprets the G-code and commands the CNC router's motors to execute the cuts.

You've just unboxed your shiny new CNC router. You've assembled it, plugged it in, and you're staring at the cutting bed, ready to bring your amazing ideas to life. But then you realize: the machine is just sitting there. How do you actually tell it what to cut and how to cut it?

Let's be clear: the physical CNC router is the muscle, but the software is the brain and the nervous system. Understanding the software workflow isn't just helpful; it's absolutely essential to making your machine do anything useful. This guide will walk you through the three key software stages.

Everything starts with an idea. CAD software is where you turn that idea into a precise digital blueprint.

This is the crucial translation step. CAM software takes your beautiful design and figures out the practical steps the CNC router needs to take to create it in the real world.

G01 X10 Y25 F300 (Move linearly to coordinates X10, Y25 at a feed rate of 300 mm/min).This is the final piece of the puzzle, the software that acts as the CNC router's direct interpreter and commander.

Operating a CNC router is a seamless dance between the digital and physical worlds, orchestrated entirely by software. By understanding the distinct but interconnected roles of CAD (designing the 'what'), CAM (planning the 'how'), and the Control Software (executing the 'do'), you gain the fundamental knowledge needed to transform your creative ideas into precisely machined physical objects. Mastering this digital thread is the key to unlocking the full potential of your CNC router.

A1: Not always. Many modern software packages, especially for hobbyist and mid-range CNC router users, combine CAD and CAM functionality into a single program (e.g., Fusion 360, Vectric VCarve, Easel). However, the Control Software is almost always separate, either running on the machine itself or on a dedicated computer connected to it.

A2: It varies wildly. There are excellent free and open-source options (like FreeCAD for CAD, LinuxCNC for control), affordable hobbyist-level programs, and professional-grade CAD/CAM suites that can cost thousands of dollars. The right choice depends entirely on your budget and the complexity of the work you plan to do.

A3: For most beginners, the steepest learning curve is usually in the CAM software. While CAD is about design, CAM requires you to think like a machinist—understanding cutting tools, material properties, and optimal strategies for removing material efficiently and achieving a good finish. This often involves some trial and error.