What is Industrial IoT (IIoT)? A Guide to the IoT for Industry

|

|

Time to read 5 min

|

|

Time to read 5 min

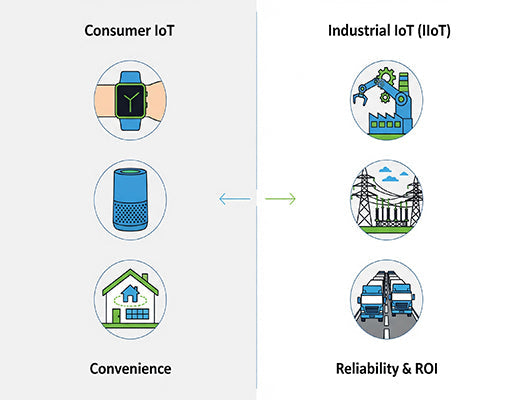

Industrial IoT (IIoT), or the Industrial Internet of Things, is the application of IoT technology specifically within industrial settings and applications. While consumer IoT focuses on convenience (like smart homes), IIoT is about connecting high-stakes industrial machinery—like factory robots, power grid components, and logistics fleets—to the internet to drive major operational improvements. By using rugged sensors and gateways to collect and analyze machine data, IIoT enables transformative strategies like predictive maintenance, remote operations, and enhanced efficiency, all aimed at tackling the multi-million-dollar problem of industrial downtime.

Industrial IoT (IIoT) is a specialized subset of IoT focused on industrial applications, prioritizing extreme reliability, security, and ROI.

The core difference between IIoT vs. IoT is the level of risk: a failed smart toaster is an inconvenience; a failed factory robot is a financial catastrophe.

IIoT works by connecting Operational Technology (OT) like PLCs and sensors with Information Technology (IT) like cloud platforms, bridging the factory floor and the data center.

The primary business driver for IIoT is the prevention of unplanned downtime, which can cost industries like automotive manufacturing over $2 million per hour.

You’ve probably heard of the Internet of Things (IoT). It’s the technology that connects our smart watches, thermostats, and coffee makers to the internet, making our daily lives more convenient. But what happens when you take that same concept and apply it not to a coffee maker, but to a half-million-dollar robotic arm on a car assembly line?

That's when IoT evolves into something far more critical. That's when it becomes the Industrial IoT.

Let's be clear: while they share a name, the world of consumer IoT and the world of Industrial IoT (IIoT) are fundamentally different. One is about convenience; the other is about preventing catastrophic failure and driving massive operational value. This guide will break down exactly what IIoT is and why it's at the heart of the fourth industrial revolution (Industry 4.0).

The best way to understand what is IIoT is to understand what it isn't. The real 'aha!' moment comes when you compare it to the consumer IoT devices you already know.

Feature |

Consumer IoT (IoT) |

Industrial IoT (IIoT) |

Primary Goal |

Convenience, user experience |

Efficiency, safety, reliability, ROI |

Consequence of Failure |

Low (A smart light fails) |

Catastrophic (A production line stops) |

Environment |

Clean, stable (Home, office) |

Harsh, demanding (Factory, outdoor, vehicle) |

Device Lifespan |

Short (2-3 years) |

Very Long (10-20 years) |

Security Stakes |

High (Privacy) |

Critical (Operational integrity, national security) |

In short, while both use sensors and connectivity, Industrial IoT is built for a world where failure is not an option.

The single biggest driver behind the adoption of IIoT is the astronomical cost of unplanned downtime. When a critical machine in a factory or a recloser on a power grid fails unexpectedly, the financial losses are staggering. Recent industry analysis shows that for a typical large industrial enterprise, the annual cost of downtime has soared to $129 million.

IIoT provides the tools to fight this. By connecting machines and analyzing their real-time health data, companies can shift from a reactive "break-fix" maintenance model to a proactive, predictive one, fixing problems before they cause a shutdown.

This layer is responsible for gathering the data from the "things" and securely transmitting it. The key piece of hardware here is a purpose-built industrial gateway or router.

This is the central software hub, often in the cloud, where the data is aggregated, analyzed, and visualized. A platform like Robustel's RCMS provides the tools for device management (monitoring the health of the gateways themselves), data storage, and creating the dashboards and alerts that drive business decisions.

Industrial IoT is not just a buzzword; it's a fundamental shift in how industries operate. It's the practical application of connectivity and data to solve the most expensive and persistent problems in the physical world. By building a robust IIoT architecture with industrial-grade hardware and a scalable management platform, businesses can unlock new levels of efficiency, safety, and resilience, laying the foundation to compete and win in the fourth industrial revolution.

A1: OT (Operational Technology) refers to the hardware and software that directly monitors and controls physical devices and processes in an industrial environment (e.g., PLCs, factory machinery). IT (Information Technology) refers to the systems used to manage data and information (e.g., servers, databases, ERP systems). A key goal of Industrial IoT is to bridge the gap between OT and IT.

A2: No, and this is a key benefit. A core function of an industrial gateway is to connect to legacy equipment using traditional industrial interfaces (like RS485 serial ports) and protocols (like Modbus). This allows you to bring your existing, reliable machinery into a modern data ecosystem without a costly "rip and replace".

A3: The best approach is to start with a specific, high-value problem, such as monitoring your most critical machine that is prone to failure. A proof-of-concept with a single sensor and an industrial gateway can quickly demonstrate the value and ROI before you commit to a large-scale, factory-wide deployment.