What is a CNC Router? A Guide to the Machine and Its Connectivity

|

|

Time to read 5 min

|

|

Time to read 5 min

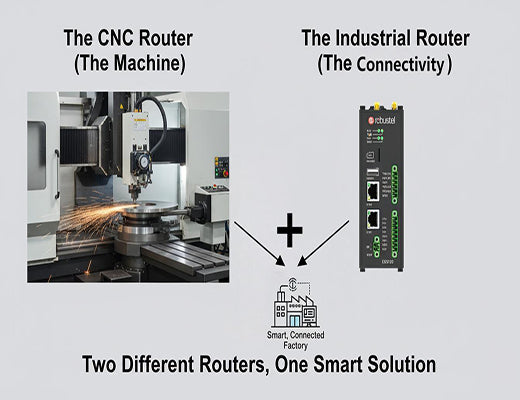

A CNC router (Computer Numerical Control router) is a computer-controlled cutting machine used to shape materials like wood, plastic, and metal. But in today's smart factories, the conversation is shifting from just what the machine does, to what data it produces. This guide will first explain what a CNC router is, and then dive into the critical, often confusing, topic of how to use an industrial router or edge gateway to connect your CNC machine to a network for remote monitoring, data collection, and predictive maintenance.

A CNC router is a machine tool that uses computer control for precision cutting. An industrial router is a network device that provides an internet connection. They are two completely different things that work together.

Connecting your industrial CNC machines to a network allows you to move from a reactive to a proactive operational model, enabling remote monitoring and reducing costly downtime.

The key to this is an industrial edge gateway, which can connect directly to the CNC's controller (often via serial or Ethernet ports) to extract valuable operational data.

This connectivity is the foundation for calculating OEE (Overall Equipment Effectiveness) and implementing advanced strategies like predictive maintenance.

I've had this happen more than once. An engineer calls me and says, "I need a router for my CNC." My first question is always the same: "Are you looking for the machine that cuts the wood, or the box that gets the machine connected to the internet?" It's a point of confusion that perfectly captures the evolution of modern manufacturing.

For decades, a CNC router was a standalone workhorse, a marvel of mechanical precision. But today, in the era of Industry 4.0, that's not enough. The most valuable thing your CNC produces might not be a physical part, but the data about how it's performing.

Let's be clear: understanding how to connect your CNC machine to your network is the first step in transforming your factory from a collection of isolated machines into a single, intelligent, data-driven operation. This guide will cover both parts of the puzzle.

First, let's establish the basics. A CNC (Computer Numerical Control) router is a machine tool that uses a computer to control a cutting tool (a router bit or spindle). Instead of an operator manually guiding the tool, the computer reads a set of instructions, typically in a language called G-code, and moves the cutting tool with incredible precision along the X, Y, and Z axes.

They are used in countless industries, from woodworking shops creating intricate furniture to aerospace factories milling complex metal parts. The core value is precision, repeatability, and automation.

The problem with most traditional CNC machines is that while they are great at their job, they are often "silent." They do their work, but they don't report back on how they are doing. This creates huge operational blind spots for a factory manager:

To answer these questions, you need to give your CNC machine a voice. You need to connect it to the network.

This is where the other kind of router comes in. An industrial edge gateway is the key to unlocking the data trapped inside your CNC machine's controller.

The real 'aha!' moment for factory managers is realizing that a single, rugged box can provide a secure, reliable bridge from their legacy machine directly to their modern monitoring dashboards.

Why go to all this trouble? Because the return on investment is massive.

A CNC router is the mechanical workhorse of modern manufacturing. An industrial edge gateway is the tool that gives that workhorse a voice, transforming it from an isolated island of production into an intelligent, data-rich node in your smart factory network. By bridging the physical and digital worlds, this simple connectivity solution is the foundation for building a more efficient, more resilient, and more profitable manufacturing operation.

A1: This depends on the age and model of your CNC controller, but you can typically access a wealth of information, including: machine status (running, idle, alarm), current program name, cycle times, part counts, feed rate overrides, spindle load, and motor temperatures.

A2: Yes, absolutely. This is a primary use case for an industrial edge gateway. A gateway like the EG5120 has built-in RS232/RS485 serial ports specifically designed to connect to and communicate with legacy industrial equipment like older CNC controllers.

A3: OEE stands for Overall Equipment Effectiveness. It's a key performance indicator that measures manufacturing productivity. It is calculated by multiplying three factors: Availability (is the machine running when it's supposed to be?), Performance (is it running at its theoretical top speed?), and Quality (is it producing good parts?).