The Total Cost of Ownership (TCO) for Industrial Routers: A Buyer's Guide

|

|

Time to read 5 min

|

|

Time to read 5 min

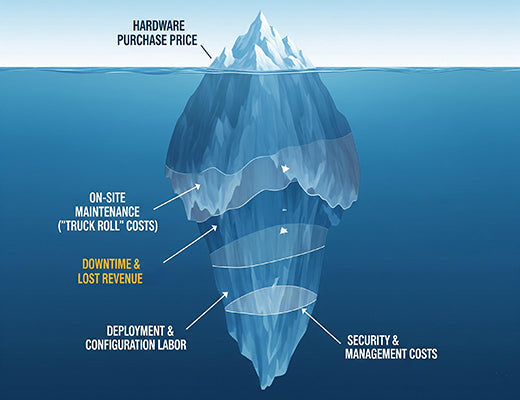

This buyer's guide to the Total Cost of Ownership (TCO) for industrial routers explains why focusing solely on the initial purchase price is a critical mistake. The true cost of an industrial router includes hidden operational expenses like deployment, maintenance, management, and the massive cost of downtime from failures. We'll break down the TCO "iceberg" and show how investing in a reliable, professionally managed router is the most financially sound decision for any serious IoT project.

The purchase price of an industrial router is just the "tip of the iceberg"; the majority of costs are hidden below the surface.

The single largest hidden cost is often "truck rolls"—the expense of sending a technician to a remote site for manual maintenance or reboots.

A powerful cloud management platform (like RCMS) is the number one tool for reducing TCO by enabling remote diagnostics, updates, and automated deployment.

A higher initial investment in a reliable router with a mature management ecosystem results in a significantly lower Total Cost of Ownership over the life of the project.

I've been in countless meetings where a purchasing manager proudly announces they saved 30% on an IoT project by choosing a cheaper, less-known industrial router. Six months later, I get a call from their frantic engineering team. The cheap routers are failing in the field, they have no way to update them remotely, and they've already spent twice their initial savings on sending technicians out for manual reboots.

They fell into the most common trap in industrial hardware procurement: they looked at the price tag, not the true cost.

Let's be clear: when you buy an industrial router, you are not just buying a piece of hardware. You are investing in a long-term operational system. The only way to make a smart financial decision is to look at the Total Cost of Ownership (TCO). This guide will show you how.

This is where cheap hardware becomes incredibly expensive.

The real 'aha!' moment for any decision-maker is when they do the math: avoiding just one truck roll per year often pays for the entire price difference between a cheap router and a professional, cloud-managed one.

When evaluating an industrial router, don't ask "What's the price?" Ask "How does this lower my TCO?"

In the world of industrial hardware, the old adage has never been truer: you get what you pay for. Focusing only on the initial purchase price is a short-term saving that almost always leads to long-term financial pain.

By shifting your perspective to the Total Cost of Ownership for industrial routers, you can make a truly informed decision. Investing in a robust, reliable, and professionally managed connectivity platform is not an expense; it's one of the highest ROI investments you can make in the long-term health and profitability of your operations.

A1: A "truck roll" is industry slang for dispatching a technician to a physical site. The cost includes not just the technician's hourly wage, but also their travel time (which can be hours for remote sites), fuel, vehicle wear and tear, and the opportunity cost of pulling them away from other valuable work. This is why it's the biggest hidden cost in most IoT deployments.

A2: Many professional hardware manufacturers, including Robustel, offer a powerful free tier for their cloud management platform (RCMS). The business model is based on the fact that a great management platform makes the hardware more valuable and sticky, leading to more hardware sales over time. Advanced, enterprise-specific features may be in paid tiers, but the core functionality for reducing TCO is often included for free.

A3: Start by mapping out the entire lifecycle of your device: 1. Procurement, 2. Deployment & Installation, 3. Ongoing Management & Monitoring, 4. Maintenance & Updates, 5. Decommissioning. For each stage, estimate the hardware, software, data, and, most importantly, the human labor costs. Be brutally honest about the potential costs of downtime and on-site service calls.