Raspberry Pi LoRaWAN Gateway: From DIY Prototype to Production

|

|

Time to read 6 min

|

|

Time to read 6 min

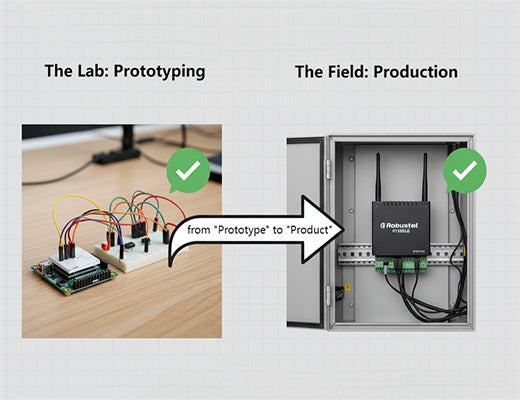

A Raspberry Pi LoRaWAN gateway is an excellent and cost-effective tool for learning, testing, and building a proof-of-concept in a lab environment. However, when it's time to move from a prototype to a scalable production deployment, the inherent limitations of a DIY solution—in hardware reliability, certifications, and remote management—become critical roadblocks. This guide directly compares the DIY approach with a professional industrial LoRaWAN gateway, providing a clear path for turning your successful prototype into a commercially viable product.

A Raspberry Pi LoRaWAN gateway is the undisputed champion for prototyping, but it is not designed for the rigors of a 24/7, unattended production environment.

The "prototype to production" gap is defined by critical industrial requirements: reliable eMMC storage (vs. a fragile SD card), integrated cellular backhaul, regulatory certifications (CE/FCC), and a scalable remote fleet management platform.

A commercial industrial gateway like the R1520LG is not a replacement for the Pi, but the logical next step for scaling a successful project, often running the exact same open-source software (like ChirpStack).

You've done it. You bought a Raspberry Pi, attached a LoRa concentrator HAT, compiled the packet forwarder, and built a working Raspberry Pi LoRaWAN gateway. Your sensors are reporting to The Things Network, and your proof-of-concept is a success. It's a fantastic achievement and a testament to the power of the maker community.

Now comes the big question I hear from so many innovators: "This works great on my desk. How do I turn this into a product I can deploy reliably in the field for my customers?"

Let's be clear: the hardware that gets you to a working prototype is rarely the hardware that gets you to a scalable product. This guide will walk through the critical differences and show you the professional path from a DIY success story to a commercial-grade solution.

We have to start by celebrating the Pi. It's the champion of the proof-of-concept for good reason:

But the very things that make it a great prototyping tool become its biggest weaknesses in a production environment.

Here's the best part: all the hard work you did developing your application on the Pi is not wasted. The migration path to a professional platform is surprisingly simple.

The real difference is that your proven open-source software is now running on reliable, certified, and remotely manageable hardware that's built for the long haul.

The debate over a Raspberry Pi LoRaWAN gateway versus a commercial industrial gateway isn't about which is "better." It's about choosing the right tool for the right stage of your project's lifecycle.

The Raspberry Pi is the perfect, indispensable tool to get you started, to test your theories, and to build a working proof-of-concept in the lab. But when your brilliant idea is ready to become a real product that your customers can rely on, a professional industrial gateway is the essential and logical next step to scale your success.

Learn more in our main guide:

A1: HAT stands for "Hardware Attached on Top." For a Raspberry Pi, it's a small add-on board that plugs directly into the Pi's 40-pin GPIO header to give it new capabilities. A LoRa HAT is a board that contains a LoRa radio concentrator, which is the chip that allows the Pi to receive LoRa messages.

A2: While a good enclosure can solve the mounting and physical protection problem, it doesn't address the more critical underlying issues: the unreliability of the SD card for storage, the commercial-grade temperature limits of the electronics, the lack of integrated cellular backhaul, and the absence of a scalable remote management solution.

A3: ChirpStack is a popular, powerful, and completely open-source LoRaWAN Network Server. It's the "brain" of the network that manages the gateways, devices, and data flow. Because it's open-source, you can run it on a Raspberry Pi for prototyping and then run the exact same software on a production-grade industrial gateway like the R1520LG for a seamless migration.